Navigating the maze of order fulfilment can be daunting for businesses aiming to meet customer expectations efficiently. Surprisingly, estimated delivery times sway a massive 68% of buyers’ decisions, highlighting the weight of swift fulfilment in driving sales.

This guide will provide you with an insightful look into optimising your customer order fulfilment process, from inventory management outsourcing fulfilment, to shipping logistics. Discover how to master the art of order fulfilment and boost customer satisfaction.

Key Takeaways

Efficient order fulfilment is critical for e-commerce success, influencing customer loyalty and brand reputation. Quick delivery and accuracy are important to 68% of customers when making purchasing decisions.

The process includes inventory management, picking and packing, shipping logistics, and handling returns efficiently. Using technology such as real-time updates helps maintain stock levels and prevent customer disappointment.

Automation greatly reduces errors in the fulfilment process by verifying inventory against orders automatically, improving speed, efficiency, and ultimately customer satisfaction.

Seasonal demand spikes necessitate advanced planning with suppliers to ensure stock availability. Diversifying carrier relationships can mitigate shipping disruptions during these peak times.

Implementing strong inventory management software like Microsoft Dynamics 365 can streamline operations from warehouse storage solutions to sales order processing.

Defining Order Fulfilment and Its Importance

Order fulfilment stands as the cornerstone of any ecommerce enterprise, a multi-step operation pivotal to ensuring that customers receive their products promptly and accurately. The significance of this mechanism lies in its direct influence on brand reputation and consumer loyalty, making it an indispensable aspect of achieving business excellence in ecommerce store.

Why efficient order fulfilment is crucial for business success

Efficient order fulfilment acts as the backbone of any successful ecommerce business. With delivery times playing a significant role in purchasing decisions for 68% of customers, streamlining this process is not just a good practice; it’s imperative for staying competitive and keeping customers happy.

Rapid and reliable fulfilment builds trust and encourages repeat business, creating a solid foundation for brand loyalty.

Mastering the art of efficient order fulfilment process translates directly into cost savings and improved customer service, ultimately allowing businesses to scale effectively. Companies that excel in fulfilling orders swiftly ensure they’re exceeding expectations while minimising delays and errors.

This proficiency in managing orders supports sustainable growth, adapting quickly to market changes, and maintaining strong supplier relationships – all vital elements contributing to ongoing success within the dynamic landscape of digital commerce.

The impact of order fulfilment on customer satisfaction

Every step in fulfilling an order shapes the customer’s experience. If a product arrives late, is damaged, or doesn’t meet expectations, customers may not only choose to shop elsewhere but also share their negative experiences with others.

A seamless fulfilment order process thus becomes essential for preserving customer satisfaction and loyalty. Quick and accurate deliveries reinforce trust in your brand, encouraging repeat business and word-of-mouth recommendations.

Handling orders swiftly signals respect for customers’ time and heightens overall satisfaction levels. Order tracking systems enable buyers to feel in control by monitoring their packages in real-time, providing reassurance from checkout until delivery.

On the other hand, efficient management of returns and exchanges can turn potential disappointments into positive outcomes that strengthen the relationship between a brand and its clientele.

Accurate demand forecasting helps maintain optimal stock levels, preventing frustration over out-of-stock scenarios while ensuring that warehouse operations run smoothly without unnecessary delays or backlogs.

Understanding the Order Fulfilment Process

Grasping the intricacies of the order fulfilment process is pivotal for businesses aiming to deliver customer satisfaction and maintain a competitive edge. This comprehensive stage involves more than just dispatching products; it’s about mastering a sequence of systematic actions that transform a customer’s demand into a delightful delivery experience.

Receiving inventory

Receiving inventory marks the critical starting point of the order fulfilment process. As goods arrive, teams meticulously inspect each shipment and swiftly report any damaged items to secure claims.

This step not only ensures quality control but also updates the inventory management system in real time, capturing accurate stock levels that are vital for fulfilling orders efficiently.

Careful attention during this phase sets a strong foundation for customer satisfaction by avoiding potential delays or errors later down the line. Efficiently managed receiving operations position businesses to meet customer demands with confidence, keeping your supply chain running smoothly and reinforcing your brand’s reputation for reliability.

Inventory storage and management

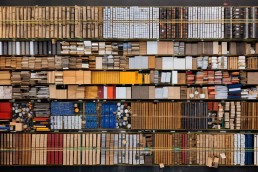

Once stock is received, the focus shifts to effective stock storage and management. Well-organised warehouses storing inventory are critical for quick and accurate order fulfilment. Every item needs a designated spot, which allows for efficient tracking and retrieval.

Ecommerce businesses rely on robust inventory management software to keep tabs on stock levels in real time. This technology is integral in avoiding stockouts that could lead to missed sales opportunities.

Directors understand that proper stock management goes beyond having enough products available; it’s about optimising the space within your warehouse or fulfilment centre. Utilising smart storage solutions maximises efficiency by minimising movement during picking processes.

By keeping high-demand items accessible, your team can pick and pack orders swiftly, ultimately enhancing customer satisfaction through timely deliveries.

Picking and packing orders

Moving from the organised world of inventory storage and management, the fulfilment process transitions to a dynamic phase with picking and packing orders. This stage is where speed meets accuracy to ensure that every item reaches its intended destination flawlessly.

Our efficient pick and pack system not only manages inventory in real-time but also turns around orders quickly while offering flexible kitting options tailored to diverse customer needs.

At this pivotal point, workers retrieve the correct products from their warehouse locations using sophisticated order picking strategies like wave or batch picking, which increase efficiency and reduce errors.

They then carefully package these items, considering factors such as dimensional weight for shipping cost optimisation. Throughout this process, meticulous quality control measures are in place.

These checks confirm that each product is packed correctly and ready for shipment, reinforcing customer satisfaction through precision-led order fulfilment orders.

Shipping and handling logistics

Once orders are meticulously picked and packed, the pivotal role of shipping and handling logistics comes into play. Efficiently managing this stage is essential for maintaining customer loyalty and achieving a competitive advantage.

It involves coordinating with reliable shipping carriers to secure the best rates and ensure that packages are delivered on time. Establishing strong relationships with these carriers can lead to preferential pricing and priority service, which is crucial in meeting tight delivery schedules.

Shipping and handling also require an intricate understanding of packaging materials, international shipping regulations, customs documentation, and expedited shipping options. Your ecommerce fulfilment system must be adept at generating accurate shipping labels, tracking inventory through SKUs (stock keeping units), and providing real-time updates to both you as the director of fulfilment operations and your customers.

This transparency throughout the order management cycle not only builds trust but streamlines the entire process from warehouse shelf to customer doorstep without unnecessary delays or complications.

Processing returns and exchanges

Processing returns and exchanges is an integral part of maintaining customer satisfaction and loyalty in the fulfilment order process. Directors should understand that a seamless return policy can be as important as the sale itself, reflecting on your brand’s reputation and customer trust.

Handling these processes efficiently requires a system that respects the consumer’s need for a simple, hassle-free experience while safeguarding the business against fraudulent claims.

Fulfilment companies step in to manage this aspect based on predetermined business rules, ensuring consistency and reliability in how returns are dealt with. They look at historical data such as return rates to help predict future trends and resource needs.

An effective strategy also involves compliance with regulations like HIPAA when handling sensitive information during product returns, crucial for businesses dealing with healthcare items.

Implementing reliable systems for processing returns helps solidify your company’s commitment to service excellence and builds lasting relationships with customers.

The Role of Order Fulfilment in Supply Chain Management

Order fulfilment is a linchpin in the mechanics of supply chain management, seamlessly intertwining with procurement, manufacturing, and distribution operations. It serves as a critical bridge between a business’s products and its market reach, determining the velocity at which customer demands are met and shaping overall supply chain execution efficacy.

How order fulfilment integrates with supply chain operations

Order fulfilment serves as the critical link between receiving customer orders and delivering satisfaction. It takes your products from warehouse shelves to customer doorsteps, acting as a bridge in the supply chain that turns purchases into experiences.

Every step within this process, from inventory management to shipping logistics, demands precision and coordination with upstream suppliers and downstream logistic partners.

Incorporating third-party logistics providers (3PLs) multiple fulfilment centres often elevates the efficiency of these operations. These specialists streamline order fulfilment processes by managing inventory storage, order processing, and distribution tasks – factors crucial for scalability in today’s booming e-commerce sector.

Their expertise ensures that handling high volumes of orders doesn’t compromise delivery speeds or service quality, keeping customers loyal and enhancing brand reputation through reliable order execution and merchant and fulfillment services.

Order Fulfilment Versus Shipping: Clarifying the Distinction

Order fulfilment encompasses the entire process from when a customer places an order to when they receive it. This includes: fulfill orders, managing inventory, processing the customer purchase order, picking items off shelves, packaging them securely, and preparing them for dispatch.

In contrast, shipping is just one segment of this journey – it’s the actual transit of products from warehouse to customer doorstep.

Distinguishing between these phases helps directors allocate resources effectively and pinpoint where enhancements can streamline operations. Good order fulfilment leads to contented customers who are more likely to return; thus mastery in this area directly contributes to business growth.

Shipping strategies also play a vital role as they impact delivery speed and costs. It is essential for directors to consider both elements as separate yet interconnected cogs in the mechanism that drives their brand’s success.

Strategies for Streamlining the Order Fulfilment Process

Efficient order fulfilment is not just about moving products from A to B; it’s also a strategic component that can significantly enhance your business’s operational efficiency and customer satisfaction.

Exploring innovative strategies for streamlining this process becomes essential in staying competitive and responsive in today’s fast-paced market environment.

Optimising inventory management

Optimising inventory management is key to cutting costs and boosting customer service. Getting it right means having the right products in the correct quantities at just the time they’re needed, with minimal excess stock.

Directors should consider Microsoft’s tools as a solid solution for managing stocks more effectively. These systems help pinpoint what items are flying off shelves and which ones are taking up valuable space.

Good inventory control streamlines operations, paving the way for seamless and efficient order fulfilment from start to finish. It takes strategic planning and smart tech integration to reach this level of efficiency.

With improved management comes better use of warehouse space, which leads naturally into our next topic: Streamlining sales order processing.

Streamlining sales order processing

Efficient sales order processing is vital for fast-paced business environments where time equates to customer satisfaction and revenue. By implementing advanced order management systems, companies can swiftly capture, track, and fulfil orders with precision, leaving little room for error.

Adopting such technology not only improves workflow but also provides a crystal-clear view of inventory levels in real-time. This ensures that products are always available when customers need them.

To turbocharge the whole order fulfilment lifecycle, embracing ecommerce order fulfilment software becomes essential. Such tools automate critical tasks from payment processing to updating stock records instantly.

They seamlessly integrate various phases of the supply chain into one comprehensive system which directors can monitor for performance insights. With these enhancements in place, handling large volumes of orders transitions from being a daunting challenge to an effortless routine that boosts overall efficiency and positions brands at the forefront of customer experience excellence.

Enhancing picking and packing efficiency

Streamlining your picking and packing processes is essential for speeding up the fulfilment of orders. Introducing advanced software systems can significantly reduce errors and increase efficiency.

For instance, warehouse management systems (WMS) allow you to track products throughout your inventory with real-time updates, leading to quicker retrieval times and accurate order assembly.

This technology supports a variety of picking methods, such as wave picking which organises order collection into waves for simultaneous processing, maximising productivity.

Another key element is equipping staff with portable devices that guide them directly to items’ locations using the most efficient routes within the warehouse. These devices often incorporate barcode scanners, ensuring that the correct product is picked every time, thereby reducing costly mistakes that can impact customer satisfaction.

By focusing on these strategic improvements, directors can expect not only reduced turnaround time but also higher throughput in fulfilling customer orders – a critical factor in scaling business operations efficiently.

Utilising technology for better accuracy and speed

Employing advanced technology reshapes the order fulfilment landscape by significantly enhancing accuracy and speed. For instance, Order management systems (OMS) leverage automation to facilitate smooth processing of orders with remarkable precision.

This innovative approach minimises human error and ensures that each step – from receiving inventory to shipping – is executed swiftly and correctly.

Integrated with real-time inventory data, these technological solutions offer directors a comprehensive overview of the entire operation. Seamless integration allows for swift responses to changing stock levels and customer demands, keeping your own fulfilment centre and service ahead of the curve.

The transformative power of tech-driven systems like ecommerce order fulfilment software lies in their ability to turn complex logistical tasks into streamlined, efficient processes that drive business growth.

The Advantages of Automating the Order Fulfilment Process

Automating the order fulfilment process transforms efficiency and accuracy, providing businesses a competitive edge in today’s fast-paced market; explore how this technology-driven approach can revolutionise your operations.

The role of automation in reducing errors

Automation plays a pivotal role in enhancing the accuracy of the order fulfilment process. By integrating advanced software and technology, businesses can significantly cut down on human oversights that lead to mistakes in orders.

Order fulfilment systems now come equipped with features that automatically verify inventory levels, match products with their corresponding SKU numbers, and confirm addresses before shipping out an item.

This not only streamlines operations but also ensures that customers receive exactly what they ordered promptly.

In the context of busy directors overseeing vast networks of distribution centres and supply chains, embracing automation is a game-changer. Sophisticated algorithms within fulfilment software solutions do more than improve speed; they conduct multiple checks at various stages of the fulfilment pipeline.

These checks minimise common blunders such as incorrect quantities or sending goods to the wrong destinations – errors which traditionally have cost companies time, resources, and customer trust.

Utilising technology like Microsoft Dynamics 365 allows for real-time updates and precise tracking from warehouse shelf to customer doorstep, demonstrating how automation supports businesses in fulfilling orders flawlessly every time.

How technology can improve order processing times

Incorporating advanced technology significantly slashes order processing times, empowering directors to exceed customer expectations. Real-time inventory updates, facilitated by digital operations platforms, prevent the delays caused by stock discrepancies.

Automated systems swiftly handle tasks that once required tedious human input; for example, they can instantly generate picking lists and validate orders against available inventory.

Leveraging technology also allows businesses to utilise data analytics effectively. This sharpens decision-making with insights that streamline workflows and optimise resource allocation.

As a result, every step in the process from receiving an order to shipping it, outsource order fulfilment and becomes faster and more efficient. Next up, we’ll explore how addressing common challenges like incorrect orders or unexpected demand spikes can further refine your strategy for seamless order fulfilment service and operations.

Order Fulfilment Challenges and Solutions

Address the complexities of order fulfilment head-on with assertive solutions to common challenges such as inventory accuracy or seasonal fluctuations that can impact customer satisfaction and business operations.

Addressing common issues like inaccurate orders and inventory shortages

Inaccurate orders can wreak havoc on a company’s reputation and customer satisfaction levels. It is critical to integrate automated systems that minimise human error, ensuring each order fulfilled aligns perfectly with the customer’s request.

This precision boosts confidence in your service and supports sustained revenue growth by securing repeat business.

Inventory shortages present another significant challenge, potentially leading to overselling and lost sales opportunities. Implementing robust inventory management practices such as real-time tracking and safety-stock protocols helps maintain an optimal stock level.

This proactive approach guarantees products are available when customers place their orders, maintaining a seamless flow in the fulfilment order process and preserving your brand’s reliability.

Strategies for managing seasonal demand and shipping complexities

Seasonal surges require a robust strategy to keep order fulfilment and shipping smooth. For starters, forecasting customer demand using historical sales data helps in stocking the right amount of inventory.

Collaborating with your suppliers well ahead of peak periods ensures you have all the products you need without overstocking or facing shortages. To tackle shipping complexities, establishing strong relationships with multiple carriers can provide alternatives when one faces delays or disruptions.

Automating parts of your logistics through third-party logistics services (3PLs) allows for better management during high-volume times. With this approach, real-time tracking and adjustments become possible, enhancing responsiveness to any supply chain hiccups.

Lastly, be proactive in communicating with customers about potential delays; transparency builds trust and reduces customer service issues related to shipping expectations.

Types of Order Fulfilment Models

Understanding the different types of order fulfilment models is essential for tailoring a solution that aligns with your business’s unique requirements and goals, ensuring that you deliver products to customers efficiently and effectively.

In-house versus third-party fulfilment (3PL)

When deliberating on whether to manage order fulfilment in-house or to outsource fulfilment to a third-party logistics provider (3PL), directors must weigh the trade-offs between control and convenience. The decision hinges on various factors, including the size of your business, volume of orders, available resources, and long-term strategic goals.

| Aspect | In-House Fulfilment | Third-Party Fulfilment (3PL) |

|---|---|---|

| Control | High level of control over operations and customer service. | Less control as operations are outsourced. |

| Costs | Lower upfront costs, but potentially higher long-term expenses. | Variable costs dependent on volume, often with negotiated rates and lower upfront investment. |

| Expertise | Dependent on in-house knowledge and training. | Access to specialised logistics expertise and industry experience. |

| Scalability | Can be challenging to scale rapidly with fluctuating demand. | Easier scalability to handle peaks without major capital investment. |

| Risk | Assumes all operational risks and responsibilities. | Shares risks with the 3PL provider, which might mitigate overall exposure. |

| Quality Assurance | Direct oversight of quality standards. | Depends on the 3PL’s quality control procedures, which may vary. |

In-house fulfilment offers directors absolute control and easier access, but may incur higher long-term costs and complexities when scaling. Conversely, third-party fulfilment provides specialised logistics expertise, scalability, and often lower upfront costs, though it can introduce concerns over quality and relinquish some degree of control. The next heading will delve into the intricacies of dropshipping and how it interplays with the fulfilment process.

Dropshipping and its impact on fulfilment

Dropshipping transforms the traditional order fulfilment process by removing the need for businesses to keep products in stock. Instead, sellers purchase items from a third party only after they have made a sale, which means the supplier handles inventory and ships directly to customers.

This approach can significantly reduce upfront costs and allow companies to offer a wider range of products without investing in large quantities of inventory.

However, dropshipping also brings challenges that impact fulfilment efficiency. The reliance on suppliers may lead to slower delivery times and inconsistent product quality since control over the shipping process is relinquished.

Customer service complexity increases when issues arise with orders fulfilled by multiple suppliers, potentially damaging customer satisfaction levels if not managed effectively. Additionally, profit margins tend to be lower due to competition and higher cost of goods sold per item compared with buying in bulk.

Despite these hurdles, many businesses find success with dropshipping during uncertain times like the COVID-19 pandemic as it provides flexibility within an ever-growing e-commerce sector.

The hybrid fulfilment model and when to consider it

The hybrid fulfilment model merges various order fulfilment strategies together, providing a tailored solution that can handle the complex demands of a diverse supply chain. Companies might opt for this approach when they’re looking to an order fulfilment provider to balance control with flexibility, or if they have varying product categories that need different handling and shipping methods.

If your business experiences fluctuations in volume due to seasonal peaks or if you sell through multiple online marketplaces alongside a brick-and-mortar store, the hybrid model could offer the agility needed to navigate these challenges effectively.

This method often blends the advantages of keeping some inventory on-hand while outsourcing excess stock to third-party logistics providers. It allows businesses to respond quickly to customer orders without overcommitting resources and capital into warehousing facilities.

In considering whether this adaptable strategy aligns with your company’s objectives, evaluate factors such as product type, sales channels, geographical reach and scalability potential.

Moving forward into selecting the right order fulfilment service will require weighing these elements carefully against service offerings and costs.

Selecting the Right Order Fulfilment Service

Selecting the optimal order fulfilment service is pivotal to ensuring your business operations run smoothly and customers receive their products swiftly and accurately. It involves a critical evaluation of various providers, weighing their capabilities against specific needs such as cost efficiency, scalability, technological integration, and overall reliability within your supply chain framework.

Factors to consider when choosing a fulfilment service provider

Selecting the right fulfilment service provider is a critical decision for any business aiming to streamline its order fulfilment processes. Directors must weigh several factors to ensure seamless operations and customer satisfaction.

Technology Integration: Assess the provider’s ability to integrate with your existing e-commerce platform and whether they offer advanced order fulfilment software solutions.

Scalability: Choose a provider that can scale operations up or down depending on your business needs, especially during peak seasons or promotional periods.

Cost Effectiveness: Consider the costs involved, including storage fees, pick-and-pack services, and shipping rates. Comparing different providers can help in finding a cost-effective solution.

Location and Reach: The location of the fulfilment centres should ideally be close to your primary customer base to reduce delivery times, which influence purchasing decisions for 68% of customers.

Speed of Delivery: Evaluate the provider’s track record for delivering orders quickly and reliably. This aspect directly affects customer satisfaction rates.

Accuracy Rate: High accuracy in picking and packing leads to fewer returns and exchanges. Providers should demonstrate their precision with data on order correctness.

Return Management: An efficient process for handling returns is essential. Check if the provider offers easy return solutions that align with your customer service standards.

Customer Service Quality: Good communication is key. Your chosen provider should offer excellent support and be responsive to both your business’s needs and those of your customers.

Inventory Management Capabilities: Effective management ensures you have real-time insights into stock levels, aiding in preventing inventory shortages or overstock situations.

Experience in Your Industry: The provider should have ample experience dealing with products similar to yours, understanding specific requirements related to packaging materials or handling regulations.

Security Measures: Ensure that the fulfilment centres have strong security protocols in place to protect your merchandise from theft or damage.

Comparing costs and services of different fulfilment options

While considering various factors is key in choosing a fulfilment service provider well, understanding the cost implications and service offerings of different fulfilment options is equally critical for decision-making. Costs and services vary between in-house operations, third-party logistics (3PLs), fulfilment companies and dropshipping models. Directors need a clear comparison to inform their strategies and operations.

| Fulfilment Option | Key Services | Cost Considerations | Pros | Cons |

|---|---|---|---|---|

| In-House | Inventory management, picking, packing, shipping | Capital investment, staffing, warehouse costs | Full control, direct oversight, brand experience | High upfront costs, scalability challenges |

| Third-Party Logistics (3PL) | Receiving, storage, pick and pack, shipping, returns | Variable fees based on storage, volume, and handling | Scalability, expertise, reduced operational burden | Less control over handling, potential for service issues |

| Dropshipping | Order forwarding, inventory management by supplier | Cost per item sold; potentially higher product costs | Low upfront investment, wide product selection | Possibly lower margins, dependency on supplier reliability |

Directors should analyse this data in relation to their company’s specific needs, considering how each fulfilment option aligns with their operational capabilities and growth objectives. The choice significantly influences logistics efficacy, customer satisfaction, and overall business agility.

Tips for Improving Your Order Fulfilment Strategy

To elevate your customer’s order fulfilment approach, delve into progressive strategies that can transform effectiveness and amplify customer contentment. Discover the implementation of best practices and analytics as instrumental tools in refining this crucial segment of your operations, setting a standard for excellence in every order dispatched.

Best practices for order fulfilment success

Streamline your order fulfilment strategy by adopting a systematic approach to inventory management. Accurate forecasting and regular cycle counts ensure you can meet customer demands without overstocking, reducing holding costs and the likelihood of stockouts.

Implementing advanced software aids in real-time tracking of inventory levels, facilitating prompt restocking when necessary, and providing insights into sales patterns.

Embrace technology to enhance the efficiency of each step in the order fulfilment process. Automated systems for picking and packing reduce human error and speed up operations. This allows for quick turnaround times from receiving an order to packing and shipping it out, helping you maintain a competitive advantage while scaling up your business operations efficiently.

Focus on building strong relationships with reliable shipping partners; prompt delivery is just as vital as correct order processing in achieving overall customer satisfaction.

Using data and KPIs to monitor and refine the fulfilment process

Building on established best practices, it’s essential to leverage the power of data and KPIs for continuous improvement in order fulfilment. Directors should harness these insights to pinpoint inefficiencies, measure accuracy, and boost overall performance.

With a sharp focus on critical metrics such as order pick time, and shipping costs, accuracy, and inventory turnover rates, businesses can ensure their strategies align with customer satisfaction goals.

Collecting this data helps identify patterns that may signal bottlenecks or opportunities for optimisation.

Implementing a robust system that tracks these key performance indicators allows for real-time monitoring of the fulfilment lifecycle. This proactive approach empowers leaders to make swift adjustments that can lead to cost savings and enhanced service delivery.

It also keeps the team aligned with evolving ecommerce market trends by providing a clear picture of where improvements are needed most. Data is invaluable; applying its insights effectively gives your company a competitive edge in order management and beyond.

The Future of Order Fulfilment

The landscape of order fulfilment is rapidly evolving, propelled by advancements in technology and changing consumer expectations. Businesses that anticipate and leverage these emerging trends will stay competitive and continue to deliver exceptional customer experiences.

Emerging trends and technologies shaping the fulfilment landscape

Emerging trends and technologies are revolutionising how businesses manage customer orders and fulfilment processes. Automation leads the charge, enabling companies to process high volumes of orders with greater accuracy and speed, a critical factor as 88% of customers show willingness to pay for same-day or expedited delivery services.

Real-time inventory systems powered by AI provide detailed insights into stock levels, reducing the risk of shortages and ensuring orders are fulfilled promptly – a key satisfaction metric for 72% of online shoppers.

Robots and drones are no longer just futuristic concepts; they’re becoming integral players in warehouse operations. These advanced machines pick, sort, and transport products more efficiently than ever before, slashing delivery times significantly.

On the consumer side, augmented reality (AR) shopping experiences blend digital convenience with tangible product interaction, leading to more confident purchases that feed directly into streamlined fulfilment channels – especially vital as e-commerce continues its upsurge post-pandemic.

With such technology at play in modern order management life cycles, directors can expect not only satisfied customers but also stronger bottom lines through efficient distribution networks.

How to Get Started with Order Fulfilment for Your Business

Initiating a streamlined order fulfilment system for your business can be transformative, paving the way to enhanced operational efficiency and customer satisfaction.

Steps to setting up an efficient order fulfilment system

Identify your specific needs by assessing the volume of orders to fulfil, the variety of products, and their storage requirements.

Choose suitable inventory management software that integrates seamlessly with your ecommerce website.

Develop detailed standard operating procedures (SOPs) for every step in your order fulfilment process.

Train your staff thoroughly on these SOPs to ensure flawless execution.

Select a strategic location for your warehouse or distribution centre to minimise shipping times and costs.

Organise your inventory with SKU numbers for easy tracking and retrieval.

Implement double – check systems at the picking stage to avoid errors in fulfilling orders.

Opt for quality packing materials to ensure products reach customers undamaged, reflecting positively on your brand.

Seal deals with reliable shipping partners capable of handling varying scales of delivery demands promptly.

Set up a responsive customer service team to handle inquiries related to order fulfilment and distribution effectively.

Conclusion: Maximising the Potential of Your Order Fulfilment Process

Concluding our comprehensive guide, we emphasise the transformative power of an efficient order fulfilment process for driving business growth and elevating customer experiences – your essential strategy for thriving in today’s competitive market awaits.

Recap of key takeaways

Implementing a dynamic and successful order fulfilment strategy is fundamental to business growth and customer satisfaction. Mastery of the entire order fulfilment process, from inventory management to shipping can result in significant reductions in costs while simultaneously boosting service levels.

Embracing technological solutions, especially e-commerce fulfilment software, is no longer optional but a necessity for staying competitive in the fast-paced online marketplace.

Directors should note that integrating sophisticated order management systems with existing supply chain operations ensures that customers receive their products promptly and accurately, reinforcing trust and loyalty.

Deploying data-driven insights allows businesses to fine-tune their approach continuously, addressing challenges such as demand fluctuations or inventory shortages proactively before they impact the bottom line.

Tailoring the fulfilment solution – be it via an in-house setup, third-party logistics (3PL), or a hybrid model – to align with company goals empowers directors to scale operations effectively without compromising on quality or efficiency.

Encouragement to invest in robust order fulfilment practices

Investing in robust order fulfilment practices is a wise move for any director looking to enhance their company’s efficiency and customer satisfaction. A solid system reduces delays, cuts costs, and scales operations effortlessly.

Consider what comprehensive fulfilment can do: transform your business into a well-oiled machine where every product reaches its destination swiftly and accurately.

Directors must recognise the power of advanced fulfilment strategies such as utilising third-party logistics (3PL) providers or embracing automation within their processes. Choices like these not only streamline workflows but also free up valuable resources so that companies can focus on growth and innovation.

Strengthening your order fulfilment backbone positions you ahead in today’s fast-paced market, ensuring customers stay loyal due to consistent reliability and speed of service delivery.

FAQs

1. What does order fulfilment mean in the world of online shopping?

Order fulfilment refers to the entire process that an online store goes through, from receiving an order to delivering the product to the customer.

2. Can you explain what B2B ecommerce order fulfilment involves?

B2B ecommerce order fulfilment covers preparing and shipping orders of products or stock keeping units (SKUs) directly between businesses rather than individual consumers.

3. What are some key steps in the order fulfilment process?

The main steps in house fulfilment will include receiving inventory, storage, processing the customer’s purchase, packing goods and finally shipping them out for delivery.

4. Why is choosing a good e-commerce fulfilment software important for my business?

Selecting efficient e-commerce fulfilment software streamlines your processes, making sure orders are fulfilled quickly and accurately within your supply chain.

5. How do third-party logistics providers fit into my business’s fulfilment method?

Third-party logistics providers handle warehousing and distributing products which can save your business time by managing tricky parts of fulfilling orders meaning you don’t have to do it yourself.

6. What is considered as the final step in a typical fulfilment process?

The final step typically involves updating inventory management systems after delivery confirmation to maintain accurate records for both merchant and customers’ ease.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...