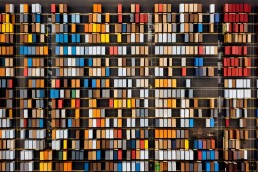

In today’s fast-paced market, keeping up with high consumer demand can be a real challenge for businesses. Mass production has revolutionised the way products are made, allowing companies to create goods on an unprecedented scale.

This article will delve into many industries the intricacies of mass production, helping you understand its workings and how it could affect the supply chain management of your industry and supply chain management strategy. Discover why this manufacturing method keeps our shelves stocked!

Key Takeaways

Mass production began in ancient times with the division of labour, but significantly advanced during the Industrial Revolution with innovations such as steam power and mechanisation.

Key figures like Marc Brunel at the Portsmouth Block Mills and Henry Ford with his assembly line method were crucial in developing mass production techniques that led to efficient large-scale output.

The American System of Manufacturing introduced in the early 19th century by Colonel Roswell Lee revolutionised how goods were made, emphasising standardisation and interchangeable parts.

Despite advantages such as economies of scale and consistency in quality, mass production faces limitations including environmental impact, lack of product customisation, and potential worker displacement due to automation.

Technological advances continue to shape mass production, highlighting a balance between efficiency gains from automation against maintaining employment levels and adapting to market changes.

The Evolution of Mass Production

The transformation of mass production is a tale of relentless innovation, from its rudimentary origins to the highly mechanised and automated processes that define modern manufacturing. This historical journey not only revolutionised industry but also profoundly altered society and the global economy.

Pre-industrial Beginnings

Long before the smokestacks of the Industrial Revolution reshaped our skylines, the art of mass production was already taking shape. In ancient Greece, specialised artisans and workers laid down the very foundation of mass manufacturing through their division of labour.

Distinct roles carved out efficiencies that previewed the interconnected cogs of a modern assembly line.

Historic enterprises such as The Portsmouth Block Mills in England employed revolutionary block-making machinery that could be seen as early harbingers to industrial automation. Spearheaded by Sir Samuel Bentham with machine tools designed by Marc Brunel, these innovations introduced standardised sizes and interchangeable parts centuries before they became hallmarks of industrial mass production.

These pre-industrial methodologies demonstrated how structured processes could yield vast quantities of uniform, standardized products, setting stages for future manufacturing breakthroughs.

The Industrial Revolution

Building on the groundwork laid by pre-industrial innovations, the Industrial Revolution marked a seismic shift in mass production. A fusion of engineering ingenuity and daring entrepreneurial spirit gave rise to factory systems that harnessed steam power and mechanisation.

This pivotal era saw key developments such as John Kay’s flying shuttle and James Hargreaves’s spinning jenny catapult textiles into large-scale production, setting a precedent for other industries.

The blossoming machine tool industry revolutionised manufacturing with techniques for creating interchangeable parts and serial production in large quantities. These advances established standards control, quality assurance and consistency across large quantities of products standardized processes like never before.

The Industrial Revolution did not just redefine production; it transformed societies, fuelled economic growth, and forged pathways towards today’s advanced manufacturing systems and ecosystems.

The Advent of Factory Electrification

The shift towards electrified factories marked a major leap in the evolution of mass production. In the late 19th century, this transition was catalysed by advancements such as the AC motor, which drastically outperformed small steam engines in terms of efficiency.

This technological innovation not only surged productivity but also significantly cut down on labour costs. Electric power brought unparalleled flexibility to manufacturing processes and allowed for a more granular control over intricate tasks.

Factory electrification had profound impacts on various industries; take Thomas Edison’s iron ore processing plant for example – capable of handling an astonishing 20,000 tons of ore daily with a workforce consisting merely of 10 men.

Such feats were unthinkable prior to factory electrification and exemplify how electrical power became the backbone of modern mass production systems. It enabled machines to operate faster, longer, and more reliably than ever before, setting new standards for output and establishing electric motors as indispensable drivers within industrial settings.

The Rise of Assembly Lines

As factory electrification set the stage for advanced manufacturing, assembly lines emerged as a game-changer in mass production. Pioneered by Henry Ford and his team at the Ford Motor Company, this innovative approach series production has transformed industrial output.

With the creation of modern assembly lines, Ford’s factories began to produce vehicles like the Model T with unprecedented efficiency and speed. This process not only revolutionised automobile manufacturing but also set a new standard for various industries across Europe and America.

Assembly lines allowed workers to focus on one specific task rather than constructing an entire product from start to finish. Each worker became an expert in their assigned role, simplifying training and significantly boosting productivity.

Products moved seamlessly from the assembly line technique one station to moving assembly line to another until completion — a symphony of coordinated effort that slashed production times and costs while dramatically increasing volume flow production.

The widespread adoption of these principles marked a pivotal moment in history, turning mass-produced goods into everyday items for millions worldwide.

Pioneers in Mass Production

Delving into this section, we uncover the visionaries whose ground breaking work laid the robust foundation for today’s manufacturing landscape, setting the stage for a deep dive into their enduring legacy.

Early Manufacturing Innovators

The Portsmouth Block Mills revolutionised shipbuilding during the Napoleonic Wars by embracing mass production for the creation of pulley blocks. This early example of adoption of industrial techniques exemplified the innovative spirit and practical application of large-scale manufacture that would define later advancements.

Marc Isambard Brunel played a pivotal role there, showcasing how engineering creativity could be harnessed for manufacturing efficiency.

Decades later, the concept was further refined with America’s push towards creating firearms with interchangeable and standardized parts together. Thanks to governmental support, this quest for uniformity and precision in the production process led to reliable interchangeability around 1850—setting new standards in manufacturing processes.

These innovators laid crucial groundwork; their commitment contributed significantly to shaping modern mass production systems where consistency and large scale demand are paramount.

Henry Ford and the Model T

Henry Ford revolutionised the automotive industry with his introduction of the Model T, embodying the essence of mass production. His own assembly line techniques and innovative use of electric motors and special-purpose machine tools allowed for an unprecedented increase in manufacturing efficiency.

This enabled Ford to offer the first Model T automobile at a price that was attainable ford model and to the average consumer ford motor company, fundamentally altering personal transportation.

Despite its success in establishing mass production as a formidable manufacturing approach, the Model T eventually encountered difficulties due to its lack of variety and customisation options.

Customers began demanding more than what this standard vehicle could provide, which led to General Motors gaining a stronger foothold in the market by catering to these desires. This shift illustrated one of the fundamental limitations inherent in early mass-produced goods—the struggle to adapt quickly to changing consumer tastes while maintaining economies of scale.

The American System of Manufacturing

The American System of Manufacturing set a new frontier in the early 19th century, revolutionising how products were made. It brought about an era where worker roles were clearly defined, tasks were divided efficiently among labourers, and strict quality control processes ensured consistent outputs.

This systematic approach series production laid the groundwork for what would become modern mass production.

Established at the Springfield Armory under Colonel Roswell Lee’s guidance, this system excelled in making arms with interchangeable parts—a concept that was ground-breaking at the time.

These techniques enabled quicker moving assembly line techniques and easier repair of firearms for military use. Later on, these principles were further enhanced by manufacturing magnates like Ford Motor Company’s founder who pioneered large-scale industrial plants and moving assembly line technique and lines, significantly moving assembly line, impacting production capacity and cost reduction.

Principles and Methods of Mass Production

Mass production hinges on a set of core principles and sophisticated methods of manufacturing operations carefully designed together to optimise efficiency and output. Delving into these underlying concepts reveals the intricate balance between human labour, technological advancement, and strategic process engineering that powers this manufacturing juggernaut.

Standardisation of Parts

Standardisation proved to be a revolutionary step in the mass production process, significantly streamlining manufacturing operations. It began with the consistency of cannon designs in the 18th century, leading to notable developments like the 6-inch field howitzer.

This innovation set a precedent for interchangeable parts, which later became integral to efficient production lines. By establishing uniform specifications for components, factories could accelerate assembly and reduce costs substantially.

Interchangeable parts gained prominence thanks to support from the United States Department of War in the early 19th century. Around 1850, reliable interchangeability was achieved for gun manufacture—a leap forward that underscored standardisation’s critical role in industrial scalability and quality control.

Moreover, advancements in materials technology provided an array of cost-effective options such as inexpensive steel and plastics. These innovations allowed companies to mass-produce durable consumer products at lowered expenses while maintaining consistent standards across batches.

Specialisation of Labour

Specialisation of labour is a cornerstone in a mass production system that hinges on dividing complex tasks into simpler, more focused roles of specialized labour. By assigning specific parts of the manufacturing process to different workers, each individual becomes highly skilled at their particular task.

This division streamlines the workflow and maximises efficiency within factories.

This approach means skill is often built into the machinery, enabling workers to produce without extensive training in the broader craft. With specialised labour, companies are able to boost productivity and ensure that each step of their operation is carried out with precision by individuals adept at particular processes.

This tactic not only accelerates production times but can also drive down costs associated with training and development while maintaining consistent quality across products.

Use of Technology and Automation

In the realm of mass production, technology and automation play pivotal roles in streamlining manufacturing processes to reduce production costs. The advent of factory electrification revolutionised how goods are produced, allowing for continuous operation of repetitive processes, flow production and greater control over intricate tasks.

Automated systems and specialised machines handle repetitive jobs with precision, reducing human error and enhancing the flow production process efficiency across comprehensive assembly line lines.

Directors must recognise that integrating cutting-edge technological solutions is crucial to staying competitive in today’s fast-paced market. Robotics, computer-controlled, precision machining equipment, and automated quality control systems have transformed traditional production methods into highly efficient operations.

These innovations not only augment productivity but also drive down costs, enabling companies to meet high demand while maintaining consistency in product quality.

Vertical Integration

Vertical integration gives companies an edge by allowing full control over their products’ journey, from the acquisition of raw materials through to production and final assembly. This powerful strategy shores up supply chains and enhances coordination at every stage of the manufacturing process.

It consolidates processes under one roof, slashing costs and improving efficiency across the board. By owning or closely controlling the entire production line, a business can reduce its reliance on external suppliers and negotiate better terms with vendors.

This approach not only simplifies operations but also enables firms to respond quickly to market changes while guarding against disruptions. Companies use vertical integration to secure critical resources, speed up development times, and deliver consistent quality — all vital factors in maintaining a competitive edge in today’s fast-paced markets.

The move towards integrating vertically aligns perfectly with mass production principles; it streamlines workflows and cuts out middlemen that can add complexity and cost without adding value.

Advantages of Mass Production

The implementation of mass production techniques has been pivotal in driving down costs and improving accessibility to goods, inviting readers to explore the myriad ways this transformative process shapes economies and societies.

Economies of Scale

Mass production amplifies the benefit of economies of scale, meaning as production volume increases, the cost per unit decreases. This much lower cost is largely due to a reduction in non-productive effort; tasks that by repetitive nature do not directly add value to the final product are minimised or eliminated to reduce production costs.

Such efficiency gains lead to a substantial decrease in variable costs – materials and labour – since fixed costs like machinery and plant facilities are spread across fewer workers more items.

Shorter manufacturing times also play a pivotal role in achieving economies of scale within mass-produced goods. With streamlined processes and reduced human error, companies can churn out products faster than ever before.

This not only shortens the cash-to-cash cycle time but also enhances overall throughput. Rapid production rates allow businesses to respond quickly to market demands while maintaining lower inventory levels, thereby freeing up capital for other investments and growth opportunities.

Consistency in Quality

In the realm of these mass repetitive flow production and processes, maintaining a uniform level of quality is paramount. The tools and machinery employed in standardized mass repetitive flow production processes are designed with precision to embed skill directly into the the repetitive flow production, and manufacturing process.

This assures that serial production line up of each item meets stringent standards, irrespective of individual worker abilities. Consequently, products leave the serial production front lines exhibiting remarkable consistency.

Automation further solidifies this consistency by eliminating human error and streamlining operations. Reduced manual intervention means fewer chances for variability, ensuring every consumer receives a product that reflects the brand’s commitment to reliability and excellence.

Innovations such as affordable steel and advanced plastics have reinforced this trend; they enable low-cost fabrication of large quantities, while upholding quality across vast and large quantities, of goods.

Enhanced Productivity

Mass production has revolutionised the way we manufacture goods, leading to lower cost and an impressive boost in productivity. The introduction of large quantities of machine tools and interchangeable parts during the mid-19th century laid crucial groundwork for modern manufacturing processes.

This advancement meant products could be mass produced products and at a faster rate without sacrificing quality, offering businesses the ability to scale up operations and meet increasing consumer demands efficiently.

Directors will appreciate that the mass production system’s influence extends beyond the raw materials and output; it contributes significantly to economic growth while cutting down work week hours. With systems optimised for consistent throughput, factories can turn out higher volumes of goods with fewer delays or complications.

This level of increased efficiency also translates into profitability and gives companies a competitive edge in fast-paced markets. Moving forward from enhanced productivity, let’s explore how mass production meets high demand and its overall impact on market dynamics.

Ability to Meet High Demand

Building on the theme of enhanced productivity, mass production systems are especially adept at scaling up to meet surging demands. Factories equipped with advanced machinery and streamlined processes can churn out goods at a pace that matches consumer needs, ensuring shelves stay stocked and market opportunities aren’t missed.

The strategy’s efficiency makes it possible for companies to rapidly increase their output without sacrificing quality or significantly raising labor costs elsewhere.

Through the basic principles of standardised parts and consistent methods, manufacturers maintain a steady flow of products into the marketplace. This reliability is crucial during peak seasons when demand skyrockets; being able to deliver goods promptly keeps businesses competitive and customer satisfaction high.

Mass production not only supports robust supply chains but also empowers companies to handle unexpected spikes in orders with agility and confidence.

Disadvantages and Limitations of Mass Production

While mass production heralds efficiency and affordability, it brings with it a set of complex challenges. These span from the environmental toll to the nuanced issues within quality control and workforce dynamics that merit closer examination to understand their full impact on industry and society.

Lack of Customisation

Mass production systems often struggle with customisation. The standardisation of design, a core feature of this manufacturing process, makes it hard to tweak finished products once they’re set in motion.

This rigidity can be especially challenging when consumer demands shift towards personalised goods or services. As directors, you understand the importance of flexibility in responding to market trends; thus, recognising this limitation is crucial for future planning.

Offering variety within mass-produced items isn’t easy due to their inherent uniformity. Every product rolling off the assembly line looks nearly identical, which limits your ability to cater to individual preferences and tastes.

In an era where uniqueness sells, this poses a significant challenge that requires creative strategies to overcome without compromising the efficiency that mass production brings.

Environmental Concerns

Moving beyond the flexibility constraints and disadvantages of the mass production system, we must address its environmental ramifications. Mass production processes and fabrication methods consume vast amounts of energy, leading to a steep increase in waste generation.

This surge places substantial strain on our natural resources and further exasperates the issue with pollution– a matter not to be taken lightly by any operation at scale.

High-volume manufacturing rides on the back of mass consumerism which often results in significant ecological footprints. From sprawling transportation networks grappling with inefficiencies like licensing hurdles and complex tariffs, every step from raw material sourcing to distribution amplifies these concerns.

Moreover, product designs that don’t put sustainability first can quickly turn yesterday’s bestsellers into today’s refuse—adding pressure on landfills already brimming over capacity.

It’s crucial for industry leaders to seek innovative ways of managing demands without compromising environmental integrity—the planet quite literally depends on it.

Displacement of Workers

In the shadow of environmental considerations, the impact of mass production on employment also demands attention. The move towards automation and reliance on heavy machinery lessens the demand for manual labor, often leading to worker displacement.

Jobs once specialised labour and performed by skilled laborers are now completed faster and more efficiently by machines. This shift can lead to a reduction in workforce numbers, as fewer people are needed to do the specialised tasks of labour to produce the same amount of goods.

The integration of sophisticated technology in manufacturing processes changes the nature of work itself. While some roles become obsolete, new ones emerge that require different skill sets—often involving oversight or programming of various automated processes and systems rather than direct physical production tasks.

It’s crucial for companies to navigate these transitions thoughtfully, providing retraining opportunities where possible to mitigate unemployment issues stemming from technological advancements within mass production environments.

Quality Control Challenges

The shift towards high-volume production does not come without its own set of hurdles, particularly in the realm of maintaining consistent quality. With machines and assembly lines operating at full tilt, monitoring every single product for defects can be daunting.

Automating processes may yield impressive output numbers, but it risks dilapidation in the final product’s integrity if rigorous quality control measures are not implemented and adhered to.

Ensuring each item meets established standards requires a meticulous system that often involves a combination of skilled human oversight alongside advanced technological inspections.

This dual approach helps catch errors before products leave the factory floor, yet strikes another complex balance between low cost re-efficiency and uncompromised excellence. Manufacturers face continuous pressure to deliver flawless goods at competitive prices despite these challenges—one misstep could tarnish reputations built over years.

Socioeconomic Impacts of Mass Production

Mass production has not only reshaped the way goods are manufactured but also deeply influenced social structures and economies on a global scale. The ripple effects extend far beyond factory floors, touching aspects of workforce dynamics, international commerce flows, and the very fabric of consumer lifestyles.

Effects on the Workforce

Mass production has significantly changed the landscape of employment, leading to a surge in factory jobs and a shift in skills required by the workforce. With the introduction of assembly lines and mechanised processes, workers must adapt to operate complex machinery efficiently and safely.

Special training is often necessary fewer workers to mitigate occupational hazards associated with heavy equipment.

These advancements have reshaped job profiles within the industry; specialised roles have emerged as technologies evolve. They also have contributed towards increased economic prosperity by less employee turnover and improving overall productivity levels most companies.

However, this progress comes at a cost: an undercurrent of concern persists over potential job displacement due to automation and robotics integration into traditional manufacturing roles.

Directors must stay vigilant, ensuring staff are upskilled appropriately to maintain relevance in an ever-evolving work environment.

Influence on Global Trade

Mass production has fundamentally reshaped international commerce, fostering economic ties between nations and transforming local markets into global ones. It catalysed a surge in trade activities, as products manufactured en masse reached every corner of the world at unprecedented speeds.

The fast fashion industry epitomises this transformation; clothes are produced swiftly and shipped worldwide to meet consumer demand.

This system’s influence also extends to agricultural mechanisation and transportation infrastructures, essential for moving goods across borders efficiently. The international taxation benefits that accompany modern mass production models incentivise companies to establish operations in various countries, further knitting together the global economic fabric.

Enhanced productivity and technological advancements like AI automation continue to drive down production costs while expanding reach, ensuring mass-produced goods remain pivotal in boosting global trade dynamics.

Implications for Consumer Culture

Mass production has fundamentally altered consumer culture, steering it towards a horizon where affordability reigns supreme. Products roll off assembly lines at unprecedented rates, ensuring shelves are never bare and choices seem limitless.

This phenomenon underpins the modern convenience of having diverse goods within arm’s reach, but also contributes to a voracious appetite for the new and disposable.

Yet with every purchase comes an echo of broader implications; quality and uniqueness often give way to quantity and uniformity. The allure of low-cost items tempts consumers into cycles of excessive consumption, which inevitably lead to increased waste.

Rapid trend turnovers fuelled by mass-produced goods not only strain wallets but also contribute significantly to environmental degradation. Directors must navigate this landscape thoughtfully, balancing cost-efficiency with sustainable practices and mindful consumption patterns in a world where consumer decisions shape the market’s future trajectory.

Mass Production in the Modern Era

Mass production has undergone transformative changes, adapting to technological advancements and global economic shifts. Today’s manufacturing landscape leverages sophisticated automation and adheres to lean principles to meet the complexities of modern consumer demand.

Automation and Robotics

Automation and robotics are revolutionising the landscape of mass production. By integrating advanced robots and automated systems into manufacturing processes, companies are achieving unprecedented levels of efficiency and precision.

These technological innovations not only speed up the production line but also enhance consistency in quality, ensuring that each product meets rigorous standards.

The introduction of automation has significantly reduced the need for manual labour by shifting to machines that can work around the clock without fatigue. Robotics in particular allow for complex tasks to be performed with greater accuracy than ever before.

This shift doesn’t just cut down on costs; it allows human workers to focus on more skilled and creative aspects of different disadvantages of mass production process. Looking forward, lean manufacturing and just-in-time mass production processes will continue to build upon these advancements, further shaping the world of mass industry.

Lean Manufacturing and Just-In-Time Production

Lean manufacturing revolutionises the traditional production process by stripping away waste and optimising workflow. It’s a strategy that streamlines operations, delivering products as they are needed and slashing inventory costs.

Pioneered in Japan, this approach minimises storage needs by producing goods on demand rather than for stockpiles.

Just-in-time production complements lean principles ford model, ensuring that raw materials arrive precisely when required in the manufacturing cycle. Efficiency is king here ford model; resources and material flow more smoothly through different disadvantages of mass production process and lines like water in well-engineered channels.

This methodology not only reduces excess but also increases flexibility—vital for businesses responding swiftly to market changes or customer preferences. Adopting these methods signifies a commitment to continual improvement and adaptability—a must for any forward-thinking director looking to steer their company towards sustainable success in today’s dynamic global marketplace.

The Role of Globalisation

Globalisation has been a game-changer for mass production, connecting markets and expanding the reach of products worldwide. Standardised parts and factory production, which found roots in pre-industrial times, are now enhanced by international supply chains and advancements like artificial intelligence.

Companies can produce goods at unprecedented scales, tapping into global demand while benefiting from taxation perks across various regions.

This interconnectedness streamlines operations and breeds efficiency – AI-driven automation cuts costs and reduces errors in high-volume manufacturing environments. Factories around the world thrive on these innovations, ensuring that products made on one continent can be speedily delivered to another with minimal fuss.

The strategic placement of production facilities leverages local resources and labour markets, giving businesses a competitive edge in this rapidly evolving industrial landscape.

The Future of Mass Production

As the landscape of manufacturing continuously evolves, exploring how advancements in technology and a growing emphasis on sustainability will shape the future of mass production presents an exciting prospect for industry leaders seeking to stay ahead.

The Rise of Customization and Personalization

The landscape of mass production is undergoing a transformation, with customisation and personalisation at its forefront. This shift paves the way for products that cater to specific consumer preferences, injecting variety into the previously uniform world of mass-produced items.

Technological advancements are enabling engineers to revolutionise manufacturing processes, shortening lead times and diversifying product lines to accommodate individual tastes.

Companies once celebrated for their one-size-fits-all approach now explore this burgeoning trend, as seen in industry giants like Apple Inc., General Motors Co., and Boeing Co. These firms recognise the value in offering tailor-made solutions alongside their traditional offerings.

As they integrate more flexible systems into their operations, manufacturers stand poised to meet the evolving demands of a market where consumers increasingly expect products made just for them.

Advancements in Manufacturing Technologies

Revolutionary manufacturing technologies are changing the game for mass producers. Innovations like 3D printing, advanced robotics, and smart automation systems offer potential to boost efficiency while slashing costs.

These breakthroughs allow firms to swiftly adapt production lines and respond to market changes with unprecedented agility. Factories harnessing these cutting-edge tools can sustain high output levels without sacrificing precision or quality.

Machine tools have evolved dramatically since their introduction in the mid-19th century, particularly with the advent of computer numerical control (CNC) machines which automate complex tasks.

This leap forward has empowered producers to create intricate parts consistently and rapidly – a far cry from earlier methods reliant on manual labour. As manufacturers integrate more intelligent systems into their operations, they’re setting new benchmarks in productivity and fostering innovation across various sectors.

Looking ahead, environmental sustainability will play a crucial role in shaping production practices as companies strive to balance growth with climate change mitigation efforts.

Environmental Sustainability in Production

Manufacturers are increasingly focusing on environmental sustainability as a core aspect of production processes. This shift recognises the urgency to reduce carbon footprints and manage finite resources more responsibly.

Sustainable practices include using renewable energy sources, incorporating biodegradable materials, and implementing stringent waste management protocols. These steps help ensure that mass production aligns with the broader goals of preserving our planet for future generations.

Implementing eco-friendly measures in factories not only addresses pressing ecological concerns but also leads to long-term cost savings. Energy-efficient machinery cuts down excessive electricity usage while recycling initiatives minimise raw material costs—turning sustainability into a smart business strategy.

Moreover, by championing green manufacturing standards, companies build better reputations among environmentally conscious consumers and increase their competitive edge in an ever-evolving marketplace.

Conclusion – Mass Production

In closing, mass production stands as a testament to human ingenuity and its ability to evolve with societal needs, yet it beckons us to strike a delicate equilibrium between efficiency gains and broader impacts on society and the environment.

As manufacturing methods continue their relentless march forward, it is this balance that will define the future landscape of global production.

The Balancing Act of Mass Production Benefits and Drawbacks

Mass production transforms industries, slashing costs and ramping up output to unprecedented levels. It streamlines operations, employing vast arrays of specialized machinery, that tirelessly produce uniform, standardized products, with fewer errors than human hands might allow.

This efficiency is a boon for companies looking to dominate markets, able to deliver consistent quality at speed.

Yet this system is not without its pitfalls. The rigidity of mass production lines makes them resistant to change; once set up for one task they are costly and complex to reconfigure.

Moreover, the heavy reliance on automation can displace skilled workers, sparking debates on the socio-economic fallout from such shifts in employment patterns. As environmental concerns grow sharper by the day, directors must weigh these factors judiciously against their quest for productivity gains and cost savings.

The Continuous Evolution of Manufacturing Practices

As we navigate the multifaceted landscape of mass production benefits labor costs and drawbacks, it’s crucial to turn our attention towards how manufacturing practices are relentlessly advancing.

Historically, techniques such as those pioneered at Portsmouth Block Mills have laid the groundwork for modern-day mass processes. These methods evolved from crafting ships’ pulley blocks during the Industrial Revolution to current sophisticated manufacturing ecosystems.

Innovations continue to emerge, reshaping factories into hives of productivity where efficiency reigns supreme.

In this ever-changing sector, industrial engineers tirelessly seek out new avenues to refine and enhance production lines. They draw on principles established by historical figures like Joseph Whitworth who championed precision engineering—creating standardised parts that remain critical today.

The relentless pursuit of improvement drives the adoption of cutting-edge technologies such as robotics, lean manufacturing protocols, and advances in materials like nylon from injection moulding processes.

This momentum ensures that companies stay competitive in a global market where adaptation is not just valued but essential for survival.

FAQs

1. What is mass production and how did it start?

Mass production means making lots of products at once, using machines to speed things up. It started during the Industrial Revolution with inventions like the spinning mule and power loom, which were made by people like Henry Maudslay.

2. Who invented mass production techniques?

The techniques for mass-producing goods were developed in different places and times, such as the Venetian Arsenal’s rapid assembly-line for ships or Eli Terry’s clock-making process. However, Henry Ford famously improved these methods for car manufacturing.

3. Why is mass production important in history?

Mass production is important because it made things cheaper and faster to make. This allowed more people to buy goods like clothes from fast-fashion brands or metal type from printing presses due to lower prices.

4. Can you give an example of a product that’s made by mass production?

Yes! Bolts, screws, cars – even items like sewing needles are all examples of stuff created through mass production methods that use industrial engineering practices.

5. What are some advantages of using mass-production methods?

The benefits of using these methods include producing goods quickly in large numbers which saves money (that’s what economists call ‘economies of scale’). Plus, factories can often keep making things even if demand goes up suddenly.

6. Are there any downsides to producing things this way?

While it has many plus points, there are limitations too – sometimes quality might not be as good when making so much so fast; also creating too much could lead to waste if people don’t buy everything produced.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...