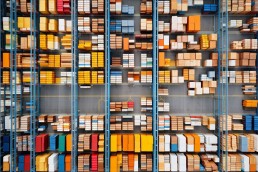

In the complex world of supply chain management, unexpected disruptions can halt production and lead to costly delays. Decoupling inventory is the strategic approach taken by businesses to navigate these challenges by maintaining a safety buffer of materials or finished products.

This article unfolds how this method stabilises operations and ensures continuity, even amid unforeseen setbacks in your supply flow. Keep reading for key insights on elevating your inventory strategy!

Key Takeaways – Inventory Decoupling

Decoupling inventory is a strategy that involves keeping extra stock at certain points in the production process to protect against disruptions and maintain smooth operations. It acts as a safety buffer, allowing businesses to continue production even if there are issues with suppliers or unexpected increases in demand.

Implementing decoupling inventory can help avoid costly delays and stockouts by ensuring materials or products are readily available when needed. This enables companies to meet customer demands promptly and maintain service levels even during periods of uncertainty or supply chain volatility.

While decoupling inventory offers significant benefits such as increased operational efficiency and reduced pressure on staff, it also requires careful management to balance the associated costs. Businesses must consider factors like carrying costs, purchasing strategies, freight rates, seasonal sales impacts, and maintaining optimal sales velocity.

Employing advanced planning systems such as ERP software is critical for managing decoupled inventories effectively. These systems provide real-time data for precise control over stock levels at decoupling points and assist in making informed purchasing decisions while minimising waste.

To successfully adopt decoupling inventory practices, firms should automate order placement systems where possible, regularly count cycle stocks for accuracy, utilise warehouse management software for real-time insights into inventory levels across locations, and consider implementing just-in-time restock triggers based on current consumption rates.

Understanding Inventory Decoupling

Decoupling inventory acts as a strategic buffer between different production stages throughout the production process, ensuring that upstream hiccups do not bring downstream operations to a standstill.

It’s essential for maintaining workflow consistency and managing lead time variations without compromising product delivery schedules or customer satisfaction. By calculating the maximum expected demand along with the longest and average lead times, businesses can define their safety stock levels effectively and ultimately customer satisfaction.

Employing decoupling stocks allows companies to respond swiftly to market changes and supply chain disruptions while keeping production lines running smoothly. This approach minimises delays in manufacturing due to shortages of raw materials or parts by bridging gaps between supplier deliveries and production needs.

Directors should view decoupling inventory as an investment in operational resilience that ultimately safeguards against lost sales opportunities caused by out-of-stock scenarios or other manufacturing line bottlenecks.

The Role of Inventory Decoupling in Supply Chain Management

Decoupling inventory serves as a critical strategic buffer, allowing supply chains to absorb and recover from disruptions with minimal impact on service levels. It acts as the fulcrum balancing between flexible supply chain continuity and demand variability, ensuring operations run smoothly even amidst unforeseen challenges.

Maintains Buffer Stock for Repairs and Maintenance

Keeping a buffer stock as part of your decoupling inventory strategy is essential for smooth operations within manufacturing industries. Should there be an unexpected equipment failure, this safety stock ensures that production can continue without significant delays.

This practice minimises downtime by providing immediate access to the necessary components for repairs and maintenance. It’s like having a spare tyre in the trunk; you hope not to need it but are grateful it’s there when you do.

Having these reserves on hand not only safeguards against potential production stoppages and halts but also upholds operational efficiency across the board. By anticipating machinery issues before they escalate into larger problems, businesses can seamlessly transition from breakdown to repair, reducing both stress on workers and potential revenue losses.

Buffer stocks act as a lifeline, offering peace of mind that even in times of trouble, crucial processes will remain uninterrupted.

Provides Protection During Periods of Uncertainty

Having a buffer stock for repairs and maintenance is crucial, but it’s the strategic use of decoupling inventory that truly shields a company’s ability during turbulent times. Economic fluctuations, natural disasters, or supplier issues can disrupt supply chains without warning.

Decoupling inventory steps in as an insurance policy here, ensuring that production lines keep moving and customer demands are met even if upstream suppliers fail to deliver.

This approach allows directors to navigate through market volatility with confidence. Regardless of external pressures or unanticipated events, decoupled inventories serve as critical stabilisers – protecting operational flows and securing business continuity.

They enable manufacturers to maintain their service levels consistently while weathering the storms of unpredictability in the supply chain landscape.

Helps to Avoid Stock Outs

Decoupling inventory is a strategic approach that equips your business with the tools to prevent costly stock outs. This system ensures products are always available, so production lines keep moving and customer orders get filled without delay.

Keeping an adequate level of decoupled inventory means you’re prepared for sudden spikes in demand or unexpected disruptions in your supply chain, keeping clients satisfied and sales steady.

Effectively managing decoupled inventory creates a safety net for your operations. It acts as an insurance policy against market volatility, enabling you to maintain service levels and reputation even when suppliers falter or logistics face hiccups.

Embracing this method arms directors with the confidence to always meet customer demand and consumer expectations consistently, supporting seamless business continuity and growth.

Inventory Decoupling vs. Pipeline Inventory

Understanding the contrasts between decoupling inventory and pipeline inventory is crucial for optimising supply chain efficiency – delve into their distinct roles and strategic advantages to master your stock management.

Similarities

Both decoupling and pipeline inventory models are integral elements of a lean supply chain, aiming to streamline operations and enhance efficiency. These systems function by strategically positioning stock at certain points in the production process or distribution network.

Their primary goal is to ensure that the flow of goods from suppliers through to customers is as smooth as possible, reducing delays and avoiding disruptions.

These strategies share a focus on maintaining an equilibrium between having enough stock to meet demand and minimising excess that can lead to waste or high holding costs. Directors know how crucial it is for inventory management systems like these to deliver reliable outcomes; they enable more accurate demand forecasting and facilitate timely order fulfilment.

In essence, both methods play a pivotal role in achieving operational excellence within warehouse management, procurement processes, and overall logistics network performance.

Differences

Moving beyond similarities, it’s crucial to distinguish between decoupling inventory and pipeline inventory to appreciate their unique roles within supply chain dynamics. Decoupling inventories are maintained on-site and readily available for immediate use, ensuring a seamless production flow by acting as a protective buffer.

In contrast, pipeline inventory consists of finished goods that have been ordered but remain in transit, thus not immediately accessible for production or sales activities.

This distinction places decoupling inventory at the heart of operational efficiency; it enables companies to remain agile amidst demand fluctuations and unexpected disruptions. Unlike pipeline stock which is dependent on supply chain continuity, decoupled stock effectively reduces downtime due to its on-hand presence – an essential differentiator for businesses aiming to maintain uninterrupted service and customer satisfaction.

How Does Inventory Decoupling Work?

Decoupling inventory, an essential part of the supply chain, aims to ensure a steady production flow. It acts as a safeguard against disruptions by maintaining a buffer of any extra raw materials, shortages or parts.

A business identifies critical stages in their production where delays are likely. At these junctures, they establish decoupling points.

Extra supplies are stored at each decoupling point. This step ensures operations can continue even if upstream activities stall.

The decoupled inventory serves as insurance. Factories can draw from it when needed without waiting for restock, hence preventing bottlenecks.

Automated systems often help manage this process. Sensors track inventory levels and trigger reorders to maintain the buffer stock.

Warehouse management software plays a crucial role too. It offers real – time insights into stock levels across different points, enabling precise control over the decoupling inventory.

Finally, regular cycle counting ensures accuracy in inventory records, which is vital for effective decoupling.

Benefits of Inventory Decoupling

Embracing decoupling inventory practices offers a multitude of advantages that streamline operations and enhance the resilience of a business’s supply chain framework. This strategic approach not merely optimises resource allocation but also equips companies with the agility to respond swiftly to fluctuating market demands and unforeseen disruptions.

Increases efficiency

Decoupling inventory streamlines the supply chain by separating buffering from fluctuating customer demand, leading to smoother operations. This strategy accelerates production processes because items are readily available, reducing time wasted waiting for components or materials.

Businesses can thus respond more quickly to market changes and client orders without sacrificing quality or service levels.

Efficient management of decoupled stock also minimises the strain on personnel, allowing them to concentrate on critical tasks and productivity improvements. The flexibility gained from an effective inventory decoupling system adapts swiftly to new circumstances, making your business agile and resilient in a competitive environment.

Skilled directors recognise that such efficiency not only drives performance but is crucial for sustainable growth and customer satisfaction.

Allows for prioritisation

Effective decoupling in supply chain operations empowers businesses to set clear priorities for their production activities. With this strategic approach, companies can safeguard critical stages of the manufacturing process by allocating resources and attention where they’re needed most, thereby ensuring continuous workflow even if certain areas experience challenges.

Decoupling inventories are carried with the foresight to address potential disruptions without impacting overall productivity.

Prioritisation is greatly enhanced through sophisticated ERP software systems that offer comprehensive visibility into a company’s inventory levels, supplier activities, purchasing needs, and warehouse management.

This advanced insight enables directors to make informed decisions quickly, prioritising tasks based on real-time data rather than estimates or guesswork. It ensures essential maintenance is never sidelined and personnel are not overburdened but supported in efficiently managing their responsibilities.

Promotes regular maintenance

Shifting focus to maintenance, decoupling inventory plays a pivotal role in ensuring regular upkeep, machinery breakdown and prevention of equipment breakdowns. By having replacement parts readily available, businesses can conduct timely preventative maintenance on machinery without experiencing downtime waiting for components.

This strategy not only minimises the risk of unexpected failures but also extends the lifespan of assets by replacing aging parts before they fail. Utilising an advanced enterprise resource planning (ERP) system aids in scheduling these maintenance activities effectively, allowing managers to keep up with essential tasks seamlessly and maintain continuous operations.

Employing this proactive approach means machines stay productive and less time is wasted on reactive measures.

Decreases pressure on personnel

Decoupling inventory significantly reduces the stress on your team. By employing effective ERP and MRP software, you create a more streamlined environment where employees can focus on critical tasks without being bogged down by constant inventory issues.

This support system not only minimises errors but also boosts morale as staff engage with work that truly benefits the business, rather than getting stuck in repetitive stock level checks and order placements.

Having this strategy in place empowers personnel to manage their responsibilities efficiently. Rather than reacting to crises or shortages, they proactively maintain supply levels and spend more time improving operations.

The decreased pressure means your experts can put their skills to better use, developing innovative solutions and driving growth within your company – a clear win for any director looking to optimise resources and cultivate a productive workplace culture.

Bolsters flexibility

Easing the strain on your team, decoupling inventory also serves to fortify flexibility in your supply chain operations. This approach allows for swift adjustments to production schedules and can seamlessly accommodate changes in customer demand.

When unexpected spikes or drops in orders occur, having a decoupled inventory system means you’re not locked into rigid processes. You have the leeway to respond without disrupting your entire operation.

With this added adaptability, your business can better navigate market fluctuations and deliver products with confidence. It ensures that individual sections of the production line aren’t forced to shut down due to a lack of materials – they have what they need when they need it.

This kind of freedom is crucial for taking on new opportunities and keeping pace with evolving industry trends without missing a beat.

The Impact of Inventory Decoupling on Business

Examining the influence of decoupling inventory on business unveils a multifaceted picture; while it can streamline operations, it also nudges adjustments in areas such as inventory costs and purchasing strategies.

Understanding this impact is crucial for making informed decisions that align with a company’s operational objectives and financial constraints.

Impact on Inventory Carrying Costs

Holding decoupling inventory in your warehouses ties up capital and can lead to high carrying costs. These expenses include storage fees, insurance, taxes, and the costs associated with items becoming obsolete over time.

Efficient management of these stocks is crucial because they can represent a significant portion of your overall inventory value – sometimes as much as 30%. To keep these costs in check, directors must ensure that inventory levels are not only sufficient but also strategically managed using advanced planning systems.

Implementing sophisticated ERP solutions helps monitor and control the carrying costs associated with decoupling inventory. By analysing data trends and consumption rates, companies can decide how much inventory or buffer stock is necessary without holding excessive amounts that increase risks and expenses.

Rotating older stock into production regularly will prevent obsolescence, maintaining product relevance and ensuring that every item held contributes positively to the company’s financial health.

Affects the Purchasing of Inventory

Decoupling inventory directly influences how businesses purchase their stock, prompting a more strategic approach to ordering supplies. With a well enough decoupled inventory system, companies are better equipped to handle sudden spikes in demand or unforeseen supply chain bottlenecks without risking overstock or capital tied up in excess inventory.

It allows for smarter purchasing decisions that align with market trends and customer needs while reducing the risk of costly write-offs from unsold goods.

Incorporating decoupling into procurement processes means firms can order smaller quantities more frequently, enhancing flexibility and responsiveness to changing conditions. This method contrasts sharply with bulk buying strategies that may seem cost-effective but often lead to unnecessary surpluses if forecasts misfire.

Decoupling ensures directors and buyers have the data needed for just-in-time purchases, maintaining optimal inventory levels tailored precisely for current consumption rates – without jeopardising the production schedule or delivery commitments.

Increases Freight Rate

Implementing a decoupling inventory strategy may inadvertently drive up your company’s freight rates. This surge is often due to the necessity of transporting additional back-up stock, which can lead to more frequent or heftier shipments.

With each extra pallet or container needed for your buffer stock, transportation costs climb – a crucial factor to consider when managing logistics expenses.

Effective coordination and strategic planning are vital in offsetting these potential cost increases. Companies succeed by ensuring that efficient use of transportation resources is at the forefront of their decoupling efforts.

Anticipating and aligning with fluctuating demand, businesses can optimise their freight transport, avoiding unnecessary expedited shipping costs that arise from supply chain hiccups.

Such acute awareness and response to logistical dynamics are essential in maintaining control over freight budgets while benefiting from decoupling inventory practices.

Hinders Seasonal Sales

Decoupling inventory pitfalls can trip up seasonal sales, leaving companies scrambling to get enough inventory to meet demand during peak periods. Without an adequate buffer of decoupling inventories from suppliers, firms might see a downturn purchase orders in crucial selling seasons, prompting a search for new vendors to fill the gap.

This juggling act disrupts not only the supply chain but also erodes customer trust and diminishes brand reputation.

Seasonal market fluctuations require responsive measures that align with consumer expectations. Firms struggling with decoupled stock levels find themselves at a disadvantage, unable to fulfill customer orders or capitalise on high-demand phases leading to potential revenue losses.

The global pandemic has underscored this vulnerability; thus underscoring the significance of optimised decoupling inventory strategies for stable seasonal sales.

Lowers Sales Velocity

Implementing decoupling inventory can sometimes create a speed bump in the flow of goods, resulting in a slower sales velocity. The buffer stock essential for riding out supply chain disruptions may inadvertently reduce the quick turnover that characterises leaner just-in-time models.

Directors need to weigh this trade-off carefully, as maintaining higher levels of safety stock through optimal decoupling inventory levels could dampen the rapid sales pace driven by market demands.

Having the additional costs of decoupling inventories means products linger longer before reaching customers, which impacts cash flow and revenue realisation cycles. It’s crucial for businesses to strike an optimal balance that minimises delays without sacrificing protection against unforeseen events that could interrupt their supply chains.

This approach ensures resilience while aiming to profit margins and keep sales velocity as brisk as possible within the constraints of sound inventory management practices.

Example of Inventory Decoupling

Consider a central processing unit (CPU) manufacturer that keeps separate inventories for different stages of their operation. They store extra microchips, a crucial component for CPUs, in case of supply chain disruptions.

This strategic choice allows the company to maintain production even if one of their suppliers fails to deliver on time. They have effectively decoupled their inventory, ensuring continuous assembly line productivity without depending on immediate chip deliveries.

Another scenario involves an e-commerce giant like Amazon-Prime, which manages a vast amount of goods across global warehouses. If a popular item suddenly spikes in demand, they rely on ready-to-ship stock placed strategically at various locations rather than waiting to restock from suppliers.

This preparedness prevents stock-outs during high-demand periods and ensures customer satisfaction with same-day or swift delivery promises – all thanks to decoupling inventory techniques that safeguard against unpredictable market fluctuations.

How to Achieve Inventory Decoupling

Mastering decoupling inventory requires a strategic approach that aligns inventory managers with your business operations, ensuring a seamless flow of goods despite the dynamics of supply and demand.

It’s about implementing smart systems and practices that not only safeguard against disruption but also enhance overall efficiency.

Automate Order Placement

Maximise efficiency in your inventory management by automating order placement. With the integration of an advanced ERP system, you ensure that stock levels are optimally maintained through timely and precise ordering processes.

This modern approach keeps production moving smoothly without manual intervention, preventing costly stockouts and overstock situations.

Embrace technology such as IoT to refine your supply chain operations further. Seamless automation in placing orders not only saves time but also reduces human error. It enables instantaneous response to changes in inventory demand, guaranteeing that your business can adapt quickly to consumer needs or market shifts.

Investing in these smart systems transforms the way you handle stock replenishment, positioning your company for successful and proactive inventory control.

Keep Buffer Stock Handy

While automating order placement streamlines the procurement process, it’s essential to couple this with maintaining a buffer stock. Having a safety net of inventory ensures your production never hits a standstill due to supply chain hiccups or sudden surges in demand.

This strategic reserve is crucial for absorbing shocks and variations that are often unpredictable, helping you maintain customer satisfaction and business continuity.

Storing decoupling inventory allows you to respond swiftly when there’s an internal demand spike or supplier delay without losing precious time. It vanishes the risk of empty shelves and lost sales that can arise from unforeseen disruptions.

Best practice necessitates calculating the right amount of buffer stock based on your maximum demand, lead time, times and demands; doing so secures your operations against interruption while keeping carrying costs in check.

Use a Warehouse Management System

Deploying a Warehouse Management System (WMS) streamlines the decoupling inventory process significantly. It provides directors with a real-time, comprehensive view of stock levels and movements across multiple locations.

This level of insight is crucial for making informed decisions on when to replenish or divert resources, ensuring that future demand for is met without holding excess inventory.

The sophisticated analytics offered by systems like WareIQ’s WMS enable businesses to track and predict trends in supply chain dynamics. With these tools at your fingertips, you can preemptively adjust buffer stocks before a potential issue escalates into a costly disruption.

Furthermore, integration with enterprise resource planning (ERP) platforms optimises the entire inventory lifecycle from supplier to customer, paving the way for more efficient operations and ultimately improved profitability.

Conclusion – Inventory Decoupling

Making inventory decoupling work for your business can lead to smoother operations and a more resilient more flexible supply chain. By embracing this strategy, companies gain flexibility in responding to market changes and improvements in internal processes.

Remember, the key is balancing stock levels with demand forecasts to maximise efficiency while minimising waste. Implementing an effective decoupling system could very well be the transformative step that keeps production flowing and customer satisfaction high in today’s fast-paced market.

Embrace these strategies, reap the benefits of reduced downtime, and watch as your business thrives despite unforeseen challenges.

FAQs

1. What does decoupling mean in the context of inventory?

Decoupling stock in supply chain refers to keeping extra stock between production steps which helps handle delays and maintain smooth operations.

2. How do you define a decoupling point?

The decoupling point is where customer orders are fulfilled from inventory, separating manufacturing from order fulfillment.

3. Why is it important for ecommerce businesses to understand pipeline inventory?

Understanding pipeline inventory enables ecommerce businesses to manage goods that are still in the process of delivery effectively, ensuring they meet demands promptly.

4. Can you explain what work-in-process inventory includes?

Work-in-process inventory is composed reserve inventory of items currently undergoing manufacturing but not yet completed or ready for sale.

5. How do online retailers benefit from implementing just-in-time (JIT) systems with their inventories?

Online retailers benefit from JIT systems as they reduce storage costs and prevent overstocking by receiving goods only as needed for sales or manufacturing.

6. What roles do dashboard tools play in managing inventory control systems?

Dashboard tools help brands and sellers monitor key performance indicators (KPIs), offering insights into stock levels, allowing quick making decisions on restocking or troubleshooting issues.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...