Navigating the intricate world of business, you might wonder how products appear on shelves and who makes and sells them. A manufacturer is the invisible giant behind every product we use, from smartphones to furniture.

This article demystifies what a manufacturer is, their types and roles in our economy, and underscores their impact on innovation and job creation. Dive in for clarity that shapes industries!

Key Takeaways

A manufacturer is vital in turning raw materials into finished goods, impacting various economic sectors by creating products that meet consumer demands.

There are different types of manufacturers: primary manufacturers who work with raw materials, secondary ones who refine these materials into products, and tertiary manufacturers who handle product distribution.

The manufacturing process includes crucial stages such as design, prototyping, mass production, and quality control to ensure market-ready products.

Manufacturers drive economic growth through job creation and investing in new technologies and infrastructure, which fosters innovation across industries.

Technological advancements within the manufacturing industry lead to increased efficiency, reduced costs and improved quality of goods while creating better opportunities for businesses and consumers.

Defining a Manufacturer

A manufacturer stands as the cornerstone entity in transforming raw materials into finished products, playing a pivotal role across diverse sectors by forging goods that cater to an array of market demands.

This fundamental agent within the supply chain not only propels economies but also ignites innovation, ensuring that consumer needs are met with precision and efficiency.

The Role of a Manufacturer in the Supply Chain

Manufacturers are the engines that drive the supply chain, transforming raw materials into finished products ready for distribution to consumers. They manage complex operations spanning pre-production planning, production, and post-production processes to ensure goods are made efficiently and delivered on time.

Skilful scheduling of these stages is vital in preventing bottlenecks and ensuring a smooth flow through the supply chain.

From deciding on procurement strategies to implementing rigorous quality control standards, manufacturers greatly influence product availability, stock, and customer satisfaction. Their choices impact lead times, which directly affect retail businesses’ ability to stock and keep shelves stocked with desired items.

Navigating this intricate web requires expertise in logistics management and clear communication lines with suppliers and distributors alike. The next segment delves into the different types of manufacturers shaping the global market.

The Various Types of Manufacturers

Delving into the diverse world of manufacturers, we find entities that used various tools to transform raw materials into treasures, each varying in their methods and end-products – a crucial exploration for any business leader seeking depth in understanding this pivotal industry within the dietary supplement manufacturing sector.

Primary manufacturers

Primary manufacturers take the reins when it comes to transforming raw materials and resources into products ready for further assembly or creation. They function as the backbone of the supply chain, often engaging in industries like steel production, textile manufacturing, and woodwork.

These businesses typically focus on one segment of a product’s journey – converting substances found in nature into usable items that secondary manufacturers then refine or incorporate into final goods.

Their operations are instrumental in manufacturing and kick-starting economic ripples across various sectors. With advancements such as automation and lean manufacturing techniques, primary manufacturers have significantly increased productivity while reducing production costs.

This not only supports a stronger global economy through job creation but also ensures that essential commodities reach markets efficiently, supplementing manufacturing and sustaining daily consumer needs without excessive delay or expense.

Secondary manufacturers

Building on the foundation laid by primary manufacturers, secondary manufacturers step in to elevate products further. Contract manufacturers (CMs) are at the heart of this category, playing a crucial part by supplement manufacturing services to sell to clients and ensuring that consumer goods meet high-quality standards while also being cost-effective to produce.

These entities take raw materials or semi-finished goods from primary producers other manufacturers and work their magic to turn them into finished products ready for market shelves.

Secondary manufacturers aren’t just important contributors to product refinement; they’re also vital for job creation and keeping production costs under control. By strategically managing lead times and employing efficient manufacturing processes, they help businesses maintain a competitive edge in their respective markets.

They empower companies with the flexibility to meet diverse consumer demands swiftly without compromising on quality or performance.

Tertiary manufacturers

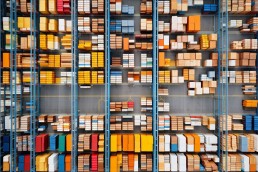

Tertiary manufacturers are the vital links that connect finished products with end-users, playing an indispensable role in ensuring goods reach the marketplace efficiently. Their operations involve a complex web of tasks including warehousing, packaging, and logistics to produce those that cater to various market demands while maintaining product integrity.

These services can help manufacturers tap into advanced technologies and develop smart inventory systems to manage diverse stock and customer requirements effectively. They streamline distribution processes so consumers and retailers can access products without delay, stress or complication.

Through their adaptive strategies and robust supply chain networks, tertiary manufacturers play a pivotal role in fulfilling consumer expectations and sustaining the flow of commerce across industries.

The Manufacturing Process Explained

Understanding the intricacies of the manufacturing process is key to appreciating the value manufacturers bring to the table. From initial design through to final production, each step contributes a vital part in transforming raw materials into finished goods that meet market demands and quality standards.

Design and Prototyping

Design and prototyping are crucial stages in the manufacturing process. They set the foundation for the creation supplement manufacturing of products and services that meet specific market demands.

Initial Designs: Manufacturers begin with conceptual designs, which involves sketching ideas or using computer-aided design (CAD) software. These initial blueprints lay out the product’s specifications and features.

Material Selection: Directors must decide on materials during this phase, balancing cost, quality, and functionality. Economical material choices can lower overall expenses without compromising product integrity.

Prototype Development: The next step is to build a prototype. This tangible representation allows manufacturers to test and refine the product’s design before mass production begins.

Testing Prototypes: Rigorous tests evaluate each prototype’s performance, durability, and safety. Feedback from these trials informs further iterations and improvements.

Cost Analysis: Estimating costs at this stage helps predict final product pricing. It enables businesses to determine if a product will be viable within their targeted market space.

Iterative Process: Design and prototyping require an iterative approach; multiple versions often precede the final design. This process ensures that every detail is honed for optimum functionality.

Stakeholder Involvement: Collaboration with stakeholders during prototyping gathers valuable insights that can lead to innovation and better customer experience outcomes.

Regulatory Compliance: Products must comply with industry standards and regulations. Ensuring prototypes pass all regulatory checks is paramount before proceeding to mass production.

Final Approval: Once a prototype meets all requirements, it receives final approval for production scaling. This transition marks the culmination of thoughtful design and rigorous testing in delivering a successful product to market.

Mass Production and Quality Control

Mass production revolutionises the way we manufacture and bring products to market, achieving economies of scale and meeting consumer demand efficiently. Quality control ensures that each item meets specific standards, reflecting a company’s commitment to excellence.

Understand the scales of manufacturing as mass – production techniques can create vast quantities of products at lower costs due to repetition and automation.

Automation plays a critical role, with machinery like assembly lines enabling consistent output while reducing manual labour requirements.

Implementing stringent quality control measures is essential throughout this process; these may include regular inspections, testing samples, and adhering to industry regulations.

Utilise advanced systems such as Enterprise Resource Planning (ERP) software to streamline operations and monitor quality assurance processes effectively.

Engage in continuous improvement strategies, like Total Quality Management (TQM), which help identify inefficiencies and increase productivity without compromising on quality.

Employ predictive maintenance programmes powered by Artificial Intelligence (AI) or Internet of Things (IoT) technologies to prevent downtime and ensure machinery’s optimal performance.

Foster skilled labour as even automated processes require human oversight; train employees thoroughly in both equipment operation and maintaining quality standards.

Embrace innovations such as additive manufacturing for customisation options in bulk production runs that traditionally relied on standardisation under mass-production methods.

Strike a balance between lead time and quality, never sacrificing the latter for quicker production rates – customers expect reliability alongside prompt service.

Consider environmental impacts by implementing eco-friendly practices within mass-production procedures; this not only helps the planet but also resonates positively with consumers.

The Importance of Manufacturers in the Global Economy

Manufacturers are pivotal in shaping the global economy, not only by fuelling economic growth and job creation but also as catalysts for fostering innovation and technological advancements.

Their operations underpin a multitude of industries and services, creating a ripple effect that benefits various sectors and contributes significantly to the wealth, health and resources of nations.

Economic Growth and Job Creation

Manufacturing industries are a powerhouse for driving economic growth, significantly contributing to the Gross Domestic Product (GDP) of developed economies. As they expand, many other manufacturers will demand more raw materials, invest in new technology and infrastructure, and create an upward spiral of economic activity.

This investment stimulates other sectors by increasing their business prospects and encouraging innovation and competition across various fields.

A critical aspect of this industry’s contribution to the economy is its role in job creation. Factories and production plants offer employment opportunities at multiple skill levels, from designers and engineers to machine operators and assembly line workers.

With each new facility or expansion project initiated by manufacturers, distributors supplement manufacturers or retailers, local communities benefit from job openings that can lead to stable income sources for countless households.

These roles not only provide livelihoods but also equip workers with valuable skills that reinforce the workforce and country’s capability as a whole.

Innovation and Technological Advancement

Manufacturers must continually embrace innovation and technological advancements to stay ahead in a competitive market. Such progress is the lifeblood of economic growth, fueling new opportunities for businesses and consumers alike.

Companies are now automating processes with robotics, integrating cloud-based services into ERP systems for streamlined operations management, and applying advanced cybersecurity measures to protect their digital service infrastructure.

Embracing cutting-edge technologies like blockchain and artificial intelligence allows manufacturers to revolutionise supply chains, bringing about unprecedented efficiency and transparency.

These innovations not only drive cost reductions but also enhance quality control across all stages of production. As the manufacturing sector evolves, directors play a crucial role in making strategic capital investments that fuel this cycle of continuous improvement and advancement.

Conclusion

Manufacturers remain crucial to the fabric of global commerce, driving forward economies with innovation and efficiency. They craft products that fill our lives, from the simplest household goods to complex machinery.

Throughout their diverse processes, they build the structures supporting today’s markets and tomorrow’s advancements. Their actions fuel job markets, create, and lead technological progress.

Understanding this critical role shines a light on just how vital manufacturing is in weaving together our economic landscape.

FAQs

1. What does a manufacturer do?

A manufacturer is a person or company that makes goods for sale, for example, using processes like assembly lines or high-tech manufacturing methods.

2. Why are manufacturers important to the economy?

Manufacturers play a critical role in the economy by contributing to GDP through mass-produced items and service, and help lower company overhead expenses through efficient business processes.

3. How has manufacturing changed since the Industrial Revolution?

Since the Industrial Revolution, spinners and weavers have been replaced by machines such as the spinning jenny and power loom, leading to faster production with inventions like just-in-time (JIT) systems improving inventory management.

4. How do I find reliable manufacturers for my ecommerce business?

Ecommerce businesses can use online directories on marketplaces like Alibaba to have their team and customers locate reputable vendors across different industries including high-tech manufacturing and fabrication services.

5. How has technology impacted modern-day manufacturing?

Technology advancements have led to mechanisation in factories with ERP software and various tools helping streamline operations; this includes automated machinery achieving flow production while ensuring quality control.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...