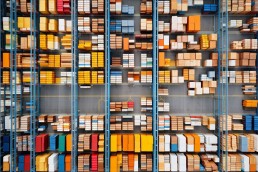

Managing inventory effectively is a common challenge for many directors seeking to strike the perfect balance between supply and demand. Surprisingly, up to 80% of a retail business’s cash can be tied up in inventory, highlighting the critical need for smart inventory planning models too.

This guide offers robust strategies and tools designed to streamline your inventory planning process, reduce costs, and enhance customer satisfaction. Dive in for the ultimate blueprint on mastering your company’s inventory landscape.

Key Takeaways

Mastering inventory planning is vital for retail businesses as it can significantly affect a company’s financial health, with up to 80% of cash potentially tied up in stock.

Smart inventory planning strategies, such as Just In Time (JIT) and Material Requirements Planning (MRP), help reduce costs, streamline operations, and improve customer satisfaction by ensuring the right products are available at the right time.

Effective inventory management avoids overstocking and understocking issues, which can lead to wasted capital or missed sales opportunities; tools like Economic Order Quantity (EOQ) aid in achieving this balance.

Forecasting future demand using historical sales data and market analysis enables companies to anticipate supply needs accurately, helping maintain consistent service levels and trust with customers.

Strong supplier relationships are crucial for maintaining an agile supply chain that can quickly adapt to changing demands whilst minimising risks related to excess inventory or insufficient stock.

Understanding Inventory Planning

Understanding Inventory Planning involves grasping the core concepts that drive efficient management of stock, ensuring businesses have the right products at the right time. It’s a strategic process distinct from assortment planning, focusing on balancing supply with current and forecasted demand to optimise operations and meet market needs.

Definition and Purpose

Inventory planning is the strategic approach to managing a company’s stock levels, ensuring that inventory is in the right place at the right time. It involves analysing data and forecasting demand to determine exactly how much inventory of product should be ordered and when it needs to be replenished.

This process keeps shelves stocked and customers satisfied while reducing excess expenditure on unused or overstocked items. Directors must grasp that effective planning of inventory aligns closely with a company’s financial health, as proper inventory management methods can release cash flow otherwise tied up in unsold products.

The purpose of this crucial aspect of supply chain management is twofold: meeting customer demand without delay and minimising holding costs associated with stored goods. By anticipating demand planning future sales through historical trends, directors can make informed decisions about both quantity and timing for ordering new supplies.

This not only optimises warehouse space but also prevents costly stockouts or surplus inventories, streamlining operations across all channels – an essential driver for profitability in retail businesses.

Inventory Planning vs. Assortment Planning

Understanding the distinction between inventory planning and assortment planning is crucial for effective supply chain management. Both are fundamental to retail success but serve distinctly different functions within the business.

| Inventory Planning | Assortment Planning |

|---|---|

| Focuses on forecasting demand and determining the optimal quantity and timing for ordering inventory. | Concentrates on selecting a product range to offer at specific times and deciding which products will be sold through various sales channels. |

| Seeks to reduce costs and maintain a balanced product mix to avoid stockouts and overstocking. | Based on seasonality and consumer demand, tailors the product offerings to each channel or location to maximise sales. |

| Requires strategic decision-making to release locked cash flow by not holding excess stock. | Demands careful product selection to meet customer expectations and drive sales in targeted channels. |

| Includes setting safety stock levels and planning for warehouse capacity. | Entails choosing the product assortment based on historical sales data, trends, and promotional activities. |

Inventory planning and assortment planning are complementary processes that, when executed effectively, contribute significantly to the company’s bottom line. Each requires careful analysis and strategic implementation to ensure that the right products are available at the right time, thus meeting customer demands and maintaining healthy cash flow.

The Importance of Inventory Planning in Supply Chain Management

In the complex dance of supply chain management, inventory planning is a crucial step that ensures companies move in harmony with demand and the whole supply chain together. Properly executed, it minimises disruptions, aligns business goals with operational capabilities, and creates a seamless flow from production to customer fulfilment.

Avoiding Overselling

Keep your loyal customers coming back by nailing your inventory control. Overselling not only tarnishes brand reputation but also invites negative reviews, which can deter future sales and damage customer trust.

Establish a robust inventory planning system that strikes the perfect balance between what’s promised and what can be delivered. This precision keeps customer satisfaction high and secures repeat business.

To avoid the pitfalls of overselling, employ data-driven forecasting tools that adapt to changing market trends and consumer behaviour. Effective use of these tools ensures you maintain optimal stock levels, mitigating risks associated with excess or insufficient inventory.

Stay ahead of supply chain complexities by leveraging technology for real-time visibility into stock counts across all channels – preventing overcommitment on popular items and ensuring promises made to customers are promises kept.

Releasing Locked Cash Flow

Effective inventory planning unlocks the potential for improving your company’s cash flow. By meticulously managing stock levels, you minimise capital tied up in excess of inventory needs. This approach frees up resources that can be directed towards growth opportunities or used to bolster other areas of the operation.

Optimising your inventory using models like Economic Order Quantity (EOQ) leads to strategic ordering – ensuring you have just enough critical stock items on hand without unnecessary surplus. It prevents funds from idling in overstocked goods, enabling a smoother and more responsive supply chain, essential for robust financial health and organisational agility.

Meeting Customer Expectations

Meeting customer expectations starts with having a keen eye on proper inventory planning and control. With successful inventory plan and the right inventory in place, companies can swiftly process orders, ensuring customers get their products without delay or error.

Keeping stock levels aligned with real-time demand allows for consistent service levels that drive customer satisfaction up. It’s about delivering what your market wants when they want it.

Inventory planners play a significant role in forging trust between a brand and its audience; they ensure promises made through advertising campaigns match the reality of product availability and delivery speeds.

As directors, you are tasked with overseeing these complex operations, always aiming for optimisation that reflects well on your brand’s reputation. Up next: navigating the intricate web of challenges inherent in inventory planning.

Key Challenges in Inventory Planning

Navigating the complexities of inventory planning, companies are faced with pivotal challenges that directly impact their operational efficiency and customer satisfaction. These obstacles range from achieving the elusive balance of stock levels maintaining production flow to accurately predicting ever-changing customer demand and fostering robust supplier relationships that can withstand market fluctuations.

Balancing Stock Levels

Maintaining the right stock levels is a delicate yet critical task for inventory planners. It requires a precise blend of data-driven forecasting and real-time insights to prevent both overstocking, which ties up capital and space, and understocking, which can lead to missed sales opportunities and disappointed customers.

With tools like Material Requirements Planning (MRP), directors can predictably manage inventory by aligning purchase orders with production schedules, optimise inventory allocation routes thereby ensuring materials are always available when needed.

Staying on top of stock also means reducing holding costs while maximising product availability across various channels – a key element in satisfying diverse customer demands in today’s omnichannel retail environments.

Careful monitoring forecast demand leads to smarter replenishment strategies that keep inventory at optimum levels without incurring excess expenses or risking stockouts. Let us now explore how predicting customer demand plays into achieving this balance effectively.

Predicting Customer Demand

Predicting customer demand requires a keen eye on trends and an analytical approach to data. Directors must leverage historical sales information, key performance indicators (KPIs), and market analysis to fuel accurate forecasts.

Seasonal changes, upcoming promotions, and shifts in consumer behaviour are essential factors that can dramatically influence demand projections. It’s not merely about guessing future needs; it’s a strategic aspect of inventory planning that demands attention to detail and the ability to interpret complex datasets.

Effective demand forecasting empowers directors with the foresight needed for precise inventory control. With sophisticated predictions at hand, companies can better manage stock levels, reducing both surplus and shortages – key challenges in maintaining a healthy supply chain balance.

By harnessing real-time data alongside these predictive analytics, organisations ensure they stay ahead of the curve in meeting their customers’ evolving needs while optimising storage costs and enhancing overall customer experience.

Managing Supplier Relationships

Consistently predicting customer demand hinges on the pillars of agility and precision in your supply chain, none more critical than fostering robust supplier relationships. Cultivating these connections is imperative for directors aiming to streamline their inventory planning processes.

Effective communication with suppliers ensures that you have the right amount of stock at hand, mitigating risks associated with both overstocking and understocking. This delicate balance directly influences cash flow management and positions your company to adeptly respond to market changes.

Beyond simple transactional interactions, building strategic partnerships with suppliers can unlock efficiencies in fulfilment that resonate through to customer satisfaction. The ability to swiftly pivot according to fluctuating demands depends heavily on a foundation of strong supplier rapport.

Leveraging such alliances not only fuels better demand forecasting but also reduces shipping costs – especially when managing inventory across multiple locations becomes complex. Your role as a director inevitably involves orchestrating this symphony of supplier inputs into a cohesive strategy for maintaining optimal inventory levels without succumbing to bottlenecks or productivity loss.

Inventory Planning Strategies

Delve into our exploration of diverse inventory planning strategies designed to streamline your stock management and boost operational efficiency – continue reading for actionable insights that can transform how you manage your inventory landscape.

Deterministic Inventory Models

Deterministic inventory models are fundamental for businesses striving to optimise stock levels and enhance cash flow. They provide a structured approach to managing inventory and help mitigate risks such as theft and product abuse.

Establishes fixed order quantities: Utilising deterministic models, companies set precise reorder points that trigger purchasing. This reduces the guesswork involved in stocking decisions and aligns orders with actual demand.

Integrates with the Economic Order Quantity formula: The EOQ model is a standard deterministic method for calculating the ideal order quantity. It helps balance ordering costs with holding costs, aiming to minimise total inventory expenses.

Supports a predictable supply chain: These models operate based on known variables, offering stability in supply chain planning. Directors can anticipate stock needs more reliably, considering consistent consumption rates and lead times.

Prevents stockouts and overstocking: A well-executed deterministic model alerts planners before items run low or exceed necessary levels. This ensures products are available when needed without tying up too much capital in surplus inventory.

Aligns with Material Requirements Planning (MRP): MRP systems depend on deterministic planning to forecast material needs and schedule production efficiently. They track current inventory levels against future requirements, streamlining manufacturing processes.

Simplifies supplier negotiations: Inventory managers can leverage data from deterministic models during discussions with suppliers to establish dependable delivery schedules and potentially negotiate better terms due to consistent ordering patterns.

Enhances budget forecasting: With fixed order sizes and schedules, financial teams can forecast budgets more accurately. This allows for tighter control over cost management within the procurement process.

Just In Time (JIT) Model

The Just In Time (JIT) model revolutionises inventory planning by aligning raw material orders from suppliers directly with production schedules. This strategy not only increases efficiency but also reduces wastage process inventory, ensuring that components arrive as they are needed in the production process.

Businesses adopting JIT can expect to see a reduction in inventory holding costs, freeing up cash flow and space within warehouses.

It tackles common challenges like overstocking and stockouts head-on, leading to more streamlined operations. With its focus on minimising surplus, the JIT approach can significantly diminish risks associated with theft and obsolescence.

Mastery of this model enables companies to respond swiftly to changes in demand, providing a competitive edge through enhanced agility and customer satisfaction rates.

Material Requirements Planning (MRP)

Material Requirements Planning (MRP) stands at the forefront of production efficiency, acting as a cornerstone for planning and inventory management. This robust process leverages software to streamline the creation of a detailed production schedule whilst ensuring that all the necessary materials are on hand.

By turning to MRP, companies unlock precision in tracking inventory levels and align their staffing requirements with anticipated output. Crucially, it integrates data from both the master production schedule and bill of materials (BOM), allowing directors to orchestrate resources effectively.

Incorporating MRP into your supply chain infrastructure translates to reduced waste and enhanced readiness for market fluctuations. It circumvents traditional paper-based systems that often lag behind real-time demands, bringing forth digital agility with inventory planner software designed for dynamic environments.

As we navigate towards just-in-time delivery models or explore Kanban replenishment methods, understanding how MRP material release plans can be tailored is vital – maximising productivity without generating excess stock becomes achievable.

Prepare now to delve into Demand Driven Material Requirements Planning (DDMRP) as our next topic of exploration in this continually evolving landscape.

Demand Driven Material Requirements Planning (DDMRP)

Demand Driven Material Requirements Planning (DDMRP) marks a significant shift in inventory management. By integrating the principles of Just In Time and traditional MRP, DDMRP positions strategic stock buffers throughout the supply chain.

These buffers respond dynamically to customer demand while providing visibility across all echelons of inventory, from raw materials to finished goods.

Implementing DDMRP allows businesses to reduce lead times few inventory cycles and create a flow-based model for supply chain efficiency. Companies can stay ahead by reacting swiftly to changes in demand, ensuring high customer satisfaction rates without excess stock that ties up capital – a smart move for e-commerce operations aiming at minimising overstock and avoiding undersupply scenarios.

Essential Inventory Planning Methods

Understanding the core methods of good inventory planning, is crucial for businesses aiming to streamline their operations and maintain a competitive edge. Whether it’s fine-tuning your Work in Progress system or implementing just-in-time delivery, choosing the right approach can transform your inventory management into a strategic asset.

Work in Progress (WIP) Model

The Work in Progress (WIP) model plays a critical role in efficient inventory planning and control. By keeping track of products partially through the production process, companies gain valuable insights into their manufacturing workflows.

This allows inventory planners to do inventory allocation routes make informed decisions about resource allocation, ensuring that materials are available when needed without overstocking.

Effective management of WIP items prevents bottlenecks in production and supports streamlined order fulfillment for e-commerce businesses. It requires a keen understanding of every stage within the supply chain and equips planners with the ability to respond swiftly to changes in demand or supply issues.

This agility is vital for maintaining customer satisfaction by avoiding delays while sustaining optimal stock levels throughout the inventory lifecycle.

Perpetual Inventory Model

Keeping track of every single item in your inventory can seem daunting; however, the perpetual inventory model simplifies this process significantly. It updates inventory records instantly whenever a sale or restock occurs.

This level of real-time accuracy allows companies to maintain a clear view of their stock levels at any point in time, making it much easier for directors and inventory planners to make informed decisions about ordering and sales strategies.

Harnessing technology plays a crucial role in the effectiveness of this model – scanning systems and integrated inventory software can ensure that each transaction is immediately reflected in the company’s inventory records.

Directors benefit from this continuous flow of information as it reduces errors, saves time on manual counts, and provides actionable data that can lead to improved supply chain management.

Inventory demand planners find value in how these updates facilitate quicker responses to market changes, ensuring customer expectations are consistently met without overstocking or shortages occurring.

Lean Inventory Tips

Shifting from the Perpetual Inventory Model brings us to the lean approach, which streamlines operations and reduces waste. Embracing lean inventory tips helps businesses maintain optimal stock levels and ensure efficiency throughout their supply chains. Here are some effective strategies that directors can implement:

Conduct ABC analysis: Prioritise your inventory into three categories – A, B, and C – based on their importance to your business revenue. This method helps you focus on items that require more attention due to their higher value.

Implement Just-in-Time (JIT) practices: Align your ordering processes with real-time demand, which minimises stock on hand and reduces storage costs.

Emphasise quality management: High-quality products reduce returns and excess inventory, so invest in robust quality control measures right from the supplier to the point of sale.

Utilise cross-functional teams: Encourage collaboration between sales, procurement, and warehouse staff to streamline the inventory process and address inefficiencies quickly.

Simplify product range: Evaluate your offerings regularly to eliminate underperforming or redundant items, simplifying your inventory management plan.

Adopt pull-based systems: Shift from a push-based system where you stock up based on forecasts to a pull-based system triggerred by actual customer demand.

Optimise supplier relationships: Work closely with suppliers for efficient replenishment cycles and embrace vendor managed inventory when feasible.

Engage in continuous improvement: Use metrics such as the inventory turnover ratio to measure how effectively you manage inventory over time and make necessary adjustments.

Enhance forecasting accuracy: Leverage data-driven forecasting methods to predict customer demand with greater precision, consequently refining reorder quantities.

Standardise procedures: Develop clear-cut protocols for order management that everyone in the supply chain understands – this will improve efficiency in handling stocks.

Employ kanban systems: Visual cues like kanban cards can signal replenishment needs within a JIT model helping maintain lean operations at all times.

Implement cloud-based ERP systems: Integrate an ERP (enterprise resource planning) system for better visibility across all distribution centres and retail outlets within your network.

Focus on training staff: Ensure that team members understand lean principles and their role in maintaining streamlined inventories through regular training sessions.

Monitor KPIs regularly: Track key performance indicators diligently; this enables proactive responses to any shifts in consumption patterns or supplier delays.

Assess technology regularly: Stay updated with emerging trends like AI-powered analytics tools so that your company remains at the forefront of efficient stock planner methodologies.

The Role of Technology in Enhancing Inventory Planning

Embracing technology streamlines inventory planning, equipping businesses with sophisticated data analytics for precise demand forecasting and ultimately shaping a more resilient supply chain.

Data-Driven Forecasting

Data-driven forecasting transforms inventory planning from guesswork into science. This powerful approach harnesses historical sales data, analyses market trends, and factors in seasonal fluctuations to predict future demand accurately.

It empowers planners to refine stock levels strategically, ultimately releasing capital otherwise tied up in excess inventory. By integrating key performance indicators (KPIs) with advanced analytics, companies can maintain optimal service levels without the risk of overselling.

Harnessing this kind of predictive power requires a robust, inventory planning solution and software. The next section will delve into how such technology not only enhances forecasting accuracy but also streamlines the entire inventory management process for your business.

The Value of Inventory Planning Software

Moving on from forecasting, inventory planning software elevates the management of stock to a new level of efficiency. Its capabilities spread across diverse facets such as location management, fulfilment, planning inventory further, and providing in-depth retail business intelligence.

This technology allows companies to not only to track inventory and sales with precision but also harness barcode scanning and POS features that streamline operations. By integrating data-driven demand forecasts into their systems, businesses gain invaluable insights that help them align their inventory with market trends and consumer needs.

Embracing such sophisticated tools transforms how a company tackles common inventory challenges like overselling or understocking. The software offers robust solutions for coordinating online sales with brick-and-mortar requirements, ensuring consistency across multiple channels.

With real-time tracking of goods sold through web stores or marketplaces and seamless integration with warehouse management systems like Microsoft Dynamics 365, directors can oversee complex supply-chain dynamics effortlessly.

Inventory Organiser tools within these platforms enable more effective stock control, acting as a linchpin between forecasted demand and actual supply levels.

How to Select the Right Inventory Planning Solutions

Choosing the ideal inventory planning software hinges on aligning its capabilities with your specific business requirements, ensuring a seamless integration into your operations for optimal results – discover how to make this critical decision in our comprehensive guide.

Aligning Features with Business Needs

Selecting the ideal inventory planning tools requires a sharp focus on your company’s unique challenges and goals. It’s essential to pinpoint features that directly address specific business functions such as demand forecasting, location management, or fulfilment planning.

A tool with robust data-driven predictive capabilities can make a marked difference in how effectively you balance stock levels against customer demand.

Invest in technology solutions that offer seamless integration with your existing systems, ensuring there is no disruption to workflow and processes are significantly streamlined. Support options should be evaluated carefully; having expert assistance readily available can safeguard against unexpected issues and help maintain uninterrupted operations.

The right choice in an inventory planning tool or software will transform data into actionable insights, steering you towards more accurate decision-making and heightened efficiency within your supply chain.

Evaluating Software Ecosystem and Resources

As you delve into the ecosystem of inventory planning software, consider its compatibility with current operations and whether it can seamlessly integrate with other tools and systems your company uses.

The right technology should bolster your existing processes, not complicate them. Check that the software offers robust support resources – from training materials to customer service hotlines – to ensure quick resolution of any issues and minimal downtime.

Crucial for directors is understanding the scalability of any potential solution; will it grow alongside your business? Opt for inventory control planners or d3 inventory management systems designed with an eye on future expansion, capable of handling increased demand without performance hitches.

These considerations keep your supply chain running smoothly while maintaining optimal stock levels across all channels.

Advantages of Effective Inventory Planning

Understanding the myriad benefits of effective inventory planning can elevate a company’s operational efficiency and market responsiveness, inviting readers to delve deeper into how this strategic approach can be the catalyst for business growth and transformation.

Optimisation of Inventory Levels

Optimising inventory levels strikes a critical balance between too much inventory and too little, ensuring your company always has just the right amount of stock to meet customer demands without tying up excess capital.

By carefully managing your inventory levels, you reduce wastage, release locked cash flow for other vital operations, and maintain a streamlined supply chain that can adapt quickly to changes in demand.

This constant balancing act requires precision and foresight but pays off by avoiding overselling scenarios and disappointing customers due to stockouts.

Effective optimisation isn’t just about having less; it’s about having smarter inventory control and planning that leverages data-driven forecasting techniques. Real-time analytics enable directors like yourself to make informed decisions on when to replenish stocks based on actual sales trends rather than hunches or outdated models.

With an inventory planner app integrating these insights into daily operations, businesses stand equipped not only for today’s demands but also those of tomorrow. Moving forward with improved cash flow management as our next point of focus ensures the benefits of optimisation translate directly into financial health for the business.

Improved Cash Flow Management

Effective inventory planning unlocks the potential for better cash flow management, crucial for directors looking to stabilise their company’s financial health. With up to 80% of a retail business’s funds tied up in stock, a well-organised and proper inventory flow management plan enables businesses to reduce unnecessary capital bind-ups.

It systematically prevents overstocking and understocking incidents that can strain resources, allowing firms to reallocate finances into growth opportunities or emergency reserves.

Crafting an accurate inventory management strategy that promotes consistent service levels safeguards against overselling, which can directly enhance cash liquidity. Improved cash flow ensures that e-commerce operations run smoothly without being hampered by delayed order fulfilment due to inventory mishaps.

This strategic approach not only sustains operational efficiency but also builds resilience against market fluctuations and demand unpredictability. Directors who master this aspect of supply chain management position their businesses competitively in the marketplace – ready for the next stage: higher customer satisfaction.

Higher Customer Satisfaction

Higher customer satisfaction is a direct result of meticulous planning. Customers experience fewer delays and stockouts, thanks to the strategic management of inventory levels. A well-implemented inventory plan ensures that popular items are always available, creating trust with your clientele who rely on your consistent supply.

Swift and accurate order fulfilment becomes the norm rather than the exception, leading to positive customer feedback and repeat business.

Inventory control done right refines product availability, resulting in happier customers who receive what they want when they want it. This not only secures their loyalty but also encourages them to advocate for your brand.

Moving forward from customer satisfaction, let’s explore how building a robust inventory plan can further elevate operational efficiency and market responsiveness.

Building a Robust Inventory Plan

Crafting a resilient inventory plan is pivotal, requiring a strategy that melds meticulous data analysis with precise forecasting to maintain an optimal balance of stock. It’s about creating a dynamic framework that not only meets current demands but can swiftly adapt to market shifts, ensuring your supply chain remains robust and responsive.

Analysing Data for Better Forecasts

To achieve better forecasts, inventory planners must delve deep into data analysis. They use historical sales information, study patterns related to seasonality and promotions, as well as keep an eye on market fluctuations that could impact demand.

Handling this complex task requires a strong grasp of key performance indicators (KPIs); without these metrics, predictions may not accurately reflect future needs.

Through rigorous analysis of past and current data trends alongside predictive modeling, businesses can make educated guesses about what their stock levels should be at any given time.

This foresight is critical in configuring reorder quantities which directly influence how effectively a company meets its customer demands while maintaining optimal inventory levels.

Looking ahead to warehouse management strategies prepares us for the next essential step: determining safety stock and warehouse capacity.

Determining Safety Stock and Warehouse Capacity

After honing in on precise data for superior forecasting, it’s pivotal to establish the appropriate levels of safety stock. This is a buffer against unexpected surges in demand or delays from suppliers.

To prevent costly stockouts that can lead to lost sales – amounting to as much as $1 trillion annually – it’s essential for an inventory planner to calculate just enough safety stock.

This calculation depends on variables such as supplier reliability, market trends, and historical sales data.

Equally imperative is gauging your warehouse capacity effectively. An overcrowded warehouse could increase operational costs and slow down fulfilment speeds while vast unused spaces signify excess spending on real estate that isn’t being put to good use.

Smart planning ensures every square foot is utilised efficiently without impeding the swift movement of goods from shelf to shipment, aligning with supply chain inventory management strategies aimed at maintaining a lean inventory and optimising turnover rates.

Continuous Monitoring and Adaptation

Having determined your safety stock, inventory status and warehouse capacity, the next vital step is to embrace continuous monitoring and adaptation in your inventory planning process. This approach ensures that your inventory plan remains dynamic, adjusting swiftly to market changes or unexpected shifts in demand.

Real-time data collection feeds into predictive analytics, empowering you to make informed decisions quickly and keep stock levels optimal.

The use of MRP software stands out as a game-changer here; it streamlines cross-functional communication and supports immediate adjustments to production schedules and purchase orders.

By integrating this technology with your operations, you operate continuously, maintain an upper hand in managing supplier relationships while driving accurate predictions for customer demand. This ongoing vigilance positions your company at the forefront of efficiency – always ready to adapt without missing a beat.

Best Practices in Inventory Planning

Implementing best practices in inventory planning is essential for any organisation seeking to streamline operations and ensure product availability. By fostering a culture of continuous improvement and strategic analysis poor inventory planning, companies can not only mitigate risks but also capitalise on opportunities for growth within their supply chain.

Setting Clear Roles and Responsibilities

Assigning distinct tasks and obligations within your inventory planning team is crucial. It ensures each member understands their specific duties, from the analyst assessing data trends to the planner managing stock levels.

This clarity eliminates confusion, accelerates decision-making processes, and enhances overall supply chain efficiency.

Ensuring everyone in the team is accountable for their segment of inventory management fosters a cohesive approach towards continuous improvement. The adoption of Kaizen principles becomes seamless as roles align with strategic goals aimed at optimising inventory turnover and availability.

Next up, let’s delve into how consolidating data within systems can further streamline your operations.

Consolidating Data within Systems

Following the establishment of clear roles and responsibilities, the next critical step is to unify all your inventory data. Directors understand that in today’s complex retail environment, a multitude of systems can hold valuable information hostage in silos.

This separation can hinder accurate inventory planning and management. By methodically consolidating historical data, sales orders, accounting records, fulfilment details, and point-of-sale figures into one cohesive system, you harness a complete view of your operations.

A unified system facilitates efficient planning of inventory workflows and provides an unobstructed lens for scrutinising supply chain dynamics. It allows directors to pinpoint discrepancies quickly and align their strategies with real-time market demands.

The consolidation process upgrades the way an inventory company anticipates customer needs while fortifying relationships with suppliers by ensuring all stakeholders are interpreting consistent information when making critical decisions on stock levels or replenishment schedules.

Proactive Demand Forecasting

Proactive demand forecasting steps beyond traditional reactive models by actively analysing historical data and retail reports from a multitude of legacy systems. This approach integrates sales orders, accounting figures, fulfilment records, and point-of-sale information to predict future customer demands accurately.

By leveraging this comprehensive data collection, businesses can anticipate market trends before they unfold, allowing for strategic inventory planning that aligns closely with consumer needs.

Employing proactive demand forecasting streamlines your supply chain inventory planning process. It cuts through the guesswork and the common pitfalls caused by fragmented data sources and human bias.

The resulting forecasts empower planners to make informed decisions that optimise stock levels across multiple locations while minimising waste and maximising opportunity capture. Directors who embrace these predictive insights set their operations up for increased efficiency and higher profitability in an ever-shifting marketplace.

Conclusion

As we conclude, mastering inventory planning marks the difference between success and stagnation in today’s dynamic market. Armed with the right strategies and cutting-edge tools, businesses can leap ahead with confidence.

They’ll unlock improved cash flow and customer satisfaction while navigating supply chain complexities effortlessly. Keep this guide close; it’s your roadmap to an optimised and inventory system that promises greater profitability and streamlined operations.

Let your business thrive by making precise, informed decisions on stock management.

FAQs

1. What is inventory planning in supply chain management?

Inventory planning in supply chain management involves controlling stock levels to meet customer demand without overstocking, using strategies and tools for optimisation.

2. How can a company plan its inventory effectively?

A company plans its future inventory needs by implementing an organised inventory process flow, employing systems like ERPs, and utilising formulas such as EOQ to maintain the right balance of stock.

3. Why is it important for retailers to have an inventory plan?

For retailers, having an inventory plan ensures they have sufficient inventory and can serve their target market efficiently with cost-effective stocking while keeping track of pricing and optimising availability.

4. Can businesses manage their stock through software?

Yes, businesses can use inventory management software for tracking their goods sold, replenishing stock levels, using inventory cycles and managing budgets seamlessly.

5. What is the role of an inventory planner?

An Inventory planner oversees planned stock levels using data analysis to ensure there’s enough product to satisfy customer needs while under inventory costs preventing excess that could lead excessive inventory go to waste.

6. Does effective inventory control contribute to ecommerce success?

Definitely! An efficient control strategy helps ecommerce businesses anticipate demand response accurately; facilitate quicker shipping times; reduce holding costs; and enhance overall service quality.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...