In a world where supply chain hiccups can turn into full-blown business crises, staying ahead of the curve is non-negotiable. Disruptions from global events have highlighted technology’s role in keeping supply chains agile.

Our article delves into groundbreaking technologies poised to revolutionise your supply chain data and management, equipping you with knowledge to thrive amidst change. Discover what’s shaping the future right here.

Key Takeaways

Technologies like 3D printing and autonomous vehicles are reducing costs and production times, enhancing supply chain efficiency.

The introduction of 5G, Big Data & Analytics, and the Internet of Things is revolutionising communication speed and data analysis capabilities in supply chains.

Blockchain technology ensures product traceability and boosts consumer trust through transparent operations from manufacturing to delivery.

Artificial Intelligence (AI) improves market prediction accuracy, inventory management, and operational decision-making processes across supply chains.

Supply Chain Digital Twins enable companies to simulate various scenarios for better operation optimisation and increased system resilience.

The Current State of Supply Chain Disruptions

Supply chain disruptions continue to dominate business discussions worldwide, with companies grappling with a blend of challenges. Extended delivery times, shortages in raw materials and components, and capacity constraints are commonplace, impacting production cycles and causing ripple effects across markets.

Fluctuations in consumer demand add layer upon layer of complexity for supply chain management (SCM). In an environment where just-in-time practices once reigned supreme, businesses now strive for balance between efficiency and resilience.

Transport bottlenecks serve as stark reminders that modern SCM tech must evolve. Ports operate beyond their limits while carriers face unprecedented strains due to increased e-commerce activity.

Technology solutions like predictive analytics are no longer futuristic ideals but necessary tools for mitigating risks associated with these ongoing disruptions. The call is clear: adaptability and innovation must direct the future course of supply chains to maintain competitiveness under the new normal shaped by global events and market dynamics.

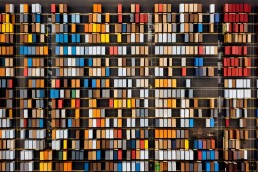

Top 10 Disruptive Supply Chain Technologies

In the vanguard of industrial innovation, a suite of disruptive technologies is poised to redefine supply chain dynamics, each bringing transformative potential to the fore. These tools not only challenge traditional paradigms but also promise unparalleled strides in efficiency and real-time decision making across global networks.

3D Printing

3D Printing, or additive manufacturing, is transforming the global supply chain landscape by democratising the production of goods. Manufacturers now have the power to create intricate designs that were previously impossible or too costly to produce using traditional manufacturing methods.

This new technology equips businesses with rapid prototyping capabilities, allowing for quicker design improvements and speedier product development cycles.

The implications for supply chain efficiency are substantial with 3D printing. Companies can now maintain leaner inventories as they shift towards on-demand manufacturing, implementing technology which curtails storage costs and minimises waste from unsold products.

The agility afforded by this tech enables a quick response to market changes or customer demands without overhauling entire production lines. Moreover, it paves the way for local production models that sidestep many logistical challenges associated with global shipping and distribution networks – slashing costs while increasing sustainability through reduced carbon emissions.

5G

5G technology is revolutionising the tech supply chain tech and chains with unprecedented speed and connectivity. Its role in enhancing communication and collaboration across the board can hardly be overstated.

Imagine your entire supply chain operating on a platform that’s not only faster but also more reliable than ever before, ensuring real-time data transfer without any lag.

The deployment of smart sensors equipped with 5G is set to transform how we track products throughout their journey. These sensors offer detailed visibility at every stage of the supply chain, from manufacturer to end-user.

The power of 5G to deliver instant updates provides directors like you with the vital information needed for quick decision-making, optimising operations and maintaining an edge over competitors in today’s fast-paced market landscape.

Augmented/Virtual Reality

Augmented and virtual reality (AR/VR) are transforming the supply chain landscape. These technologies offer immersive experiences that enable supply chain managers to visualise complex operations in real time.

They can inspect products, navigate through warehouse simulations, and train employees with interactive 3D models – all from a remote location.

Implementing AR/VR solutions empowers businesses to sharpen their decision-making capabilities. Such innovative tools reduce costly mistakes by allowing for thorough analysis before the physical work begins.

They also enhance productivity by streamlining tasks like picking and packing goods in distribution centres or simulating logistic scenarios to identify potential inefficiencies. Digital twins further complement AR/VR by offering predictive analyses, which refine on-time delivery routes and operational efficiency – key components for staying competitive in an ever-evolving tech supply chain world.

Autonomous Vehicles

Autonomous vehicles are transforming the logistics landscape, bringing unparalleled levels of efficiency and precision to supply chain operations. Self-driving trucks, which are currently being developed by tech giants and transportation companies such as Waymo and Uber, promise a future where deliveries are faster and more reliable.

This innovation alone has the potential to slash operating costs in trucking by a staggering 45%, signalling significant savings for businesses that incorporate autonomous fleets.

In warehouse environments, drones fly through aisles with pinpoint accuracy, streamlining inventory management in ways previously deemed impossible. They whizz past shelves picking products or scanning stock levels, their presence becoming an invaluable asset for companies aiming to bolster their warehouse capacity and efficiency.

As these vehicles continue to evolve under AI’s watchful algorithms, they not only minimise human error but also reimagine what’s possible in terms of delivery speeds and route optimisation – ushering in a new era of technology-driven supply chain management poised for unprecedented growth and transformation.

Big Data & Analytics

Shifting gears from autonomous vehicles, Big Data & Analytics steps up as the game-changer in harnessing vast amounts of information for strategic advantage. Supply chain and manufacturing operations can now lean heavily on big data to pinpoint trends, predict demands, and identify potential bottlenecks before they escalate into major issues.

Directors understand that these analytics are not just number-crunching exercises; they’re a beacon guiding smarter decisions across the entire supply chain ecosystem.

Real-time data analytics and predictive methods are transforming how companies approach inventory optimisation, demand forecasting, and risk management. With AI-driven tools increasingly integrated within business processes, directors see more than figures – they uncover insights that automate procurement strategies and elevate customer service levels.

This evolution paves the way for predictive modelling capable of revolutionising everything from fleet management to supplier selection, making advanced analytics an indispensable element for forward-thinking supply chains.

Robotics Process Automation

Moving from the realm of data, Robotics Process Automation (RPA) is revolutionising the way supply chains operate. RPA tools take on mundane, repetitive tasks that once bogged down human workers.

They handle duties such as processing purchase orders, updating inventory levels, and tracking shipments with precision and speed. These automated robots are not just efficient; they work around the clock without fatigue or error, dramatically boosting productivity.

Implementing RPA in supply chain management means companies can streamline their operations like never before. This leads to lower operational costs and faster response times to market demands.

With robots handling routine tasks, human employees can focus on more strategic activities – those requiring critical thinking and decision-making skills that machines have yet to master.

As a director overseeing complex systems within your organisation, integrating robotics process automation presents a clear path to enhanced performance, customer satisfaction and competitiveness in an evolving tech-led landscape.

Internet of Things

Building on the advancements in Robotics Process Automation, the Internet of Things (IoT) takes connectivity in industrial manufacturing a leap further by enabling devices across your supply chain to communicate with each other.

From warehouse sensors that monitor temperature and humidity, to tags that provide real-time location data for shipments – IoT is revolutionising how we track and manage assets. It harnesses billions of device-embedded sensors for seamless data exchange, driving operational efficiencies to new heights.

Leveraging IoT technology, companies gain unparalleled insights into every aspect of their operations. Real-time visibility into goods movement enhances security while predictive maintenance ensures machinery uptime is maximised.

This smart network not just streamlines inventory management but also sharpens forecasting accuracy, ensuring delivery estimates are reliable and much more precise. By integrating IoT into your tech supply chain infrastructure, you’re setting the stage for a dynamic system where informed decision-making becomes the norm and efficiency defines your business success.

Cloud Computing

Cloud Computing is fundamentally transforming the technical supply chain, offering unparalleled access to data and resources. It empowers supply chain organisations to effectively manage vast datasets without investing heavily in physical infrastructure.

By adopting cloud-based software, supply chains become more agile, collaborative and responsive to market demands. Cloud technology enables seamless integration of various functions from procurement to distribution centers, ensuring real-time tracking and improved decision-making.

Harnessing the power of the cloud also promotes transparency across all stages of a supply chain risk management and product’s lifecycle management (PLM), from manufacturing processes through to delivery. This shift towards cloud computing in supply chain management allows for strategic sourcing with a high degree of reliability and data quality.

The convenience of accessing information anytime, anywhere streamlines operations, reduces costs associated with traditional IT setups and drives innovation within emerging technologies in logistics and supply chain management.

Blockchain

Blockchain is revolutionising the whole supply chain industry, instilling a level of transparency and traceability that was once deemed unattainable. Imagine every product’s journey being recorded in real time, creating a digital ledger that’s both secure and tamper-proof.

This technology offers retailers and consumer-packaged-goods manufacturers unprecedented insights into their operations, ensuring ESG goals are met with concrete evidence. Blockchain’s impact extends beyond mere tracking; it fosters trust amongst stakeholders by ensuring authenticity and ethical sourcing practices.

Companies lead the way among supply chain players with impressive use cases demonstrating blockchain’s potential within the supply chain sphere. Walmart’s initiative to monitor lettuce from farm to shelf has set new standards for food safety, while SAP’s venture with Bumble Bee Foods showcases how yellowfin tuna’s path can be followed seamlessly from ocean to aisle.

These practical applications underscore blockchain as not just an innovation but as a fundamental shift in managing intricate and resilient supply chain networks efficiently and responsibly.

AI & Machine Learning

AI and machine learning are revolutionising the tech supply chain by automating processes and introducing unparalleled levels of automation. They streamline operations, make sense of complex data, and empower decision-makers with actionable insights.

These technologies can predict market changes, optimise inventory levels, and even anticipate maintenance needs for machinery. As a result, they hold the potential to dramatically cut costs while boosting efficiency across various stages of supply chain management.

Implementing AI-driven solutions transforms how suppliers manage their resources and respond to consumer demand. Machine learning algorithms refine themselves over time, ensuring that systems become smarter with each transaction.

This constant improvement leads to more accurate forecasting and better resource allocation within warehouses industries or in freight monitoring applications. By harnessing these powerful tools, directors can guide their companies towards a future where smart manufacturing is not just an ideal but an everyday reality.

The Impact of Technology on Supply Chain Management

As supply chain management embraces a technological revolution, the integration of innovative tools and systems is transforming operations from the ground up. This seamless merger not only streamlines workflows but also heralds a new era of strategic advantage, with tech-driven capabilities reshaping how industries forecast demand, manage inventories, and respond to complex market forces.

Improved Supply Chain Communication

Modern supply chain management thrives on robust communication; 5G technology is at the heart of this evolution. It unlocks faster, more reliable connections that enhance collaboration between suppliers, manufacturers, and distributors.

Imagine real-time updates whizzing across networks, facilitating swift decision-making and problem-solving without the lag that once hampered logistics.

Smart sensors equipped with 5G are revolutionising how we monitor goods. These tiny tech marvels ensure that every item’s journey is visible, cutting through the complexity to keep all players informed.

This transparency not only boosts efficiency but also refines the inventory control, tracking and management – essential in today’s fast-paced markets.

Greater Efficiency in Supply Chain Processes

Leveraging new technologies is pivotal for streamlining supply chain processes. With the implementation of big data and analytics, companies can make strategic decisions quicker and with greater confidence.

These tools provide actionable insights that automate critical operations, cut down on inefficiencies, and lead to significant cost savings. Supply chains become more responsive and adaptable to market changes when every step of the process is backed by accurate, real-time data.

Incorporating advanced technology like IoT devices revolutionises how information flows through the supply chain. Sensors placed throughout the journey of a product offer continuous updates on its status, enabling a hyper-connected network that predicts issues before they escalate.

This intricate web of interconnectedness not only improves response times but also refines inventory management – leading to smarter safety stock levels and reduced waste. By embracing these tech-driven enhancements, directors can ensure their supply chains are running at peak efficiency.

More Transparency in Supply Chain Visibility

Transparency in supply chain visibility has become a pivotal factor for businesses aiming to streamline operations and reinforce trust with stakeholders. Utilising advanced digital technologies, like blockchain, companies are now capable of providing real-time data on the provenance of goods, from manufacturing all the way through to delivery.

This level of detail empowers purchasing managers and directors with unparalleled insights into their supply chain system, enabling swift decision-making and increased accountability.

Projects such as HAPAG LLOYD’s track and trace initiative for container fleets exemplify this shift towards comprehensive transparency. Equip your supply chain with IoT sensors or integrate AI algorithms to monitor inventory levels meticulously, ensuring that every link in your logistics network is visible.

The era of guesswork is over; rigorous visibility is reshaping how we all manage inventory and our supply chains – paving the way for innovations like automatic sorting systems and market-intelligent sourcing software discussed next.

Upcoming Supply Chain Technologies

The horizon of supply chain management is rapidly advancing as emerging technologies promise to revolutionise efficiency and performance. Anticipate a wave of innovation, where sophisticated systems not only respond to challenges but also foresee them, catapulting supply chain leaders and the industry into a new era of strategic foresight business innovation and operational excellence.

Automatic Sorting and Retrieval Systems

Automatic Sorting and Retrieval Systems (AS/RS) are reshaping the landscape of warehouse management. By automating the core processes, these systems significantly reduce the need for manual labour and optimise space utilisation within facilities.

They quickly locate, pick, and transport products using advanced algorithms, delivering them to designated areas with precision. This technology is a game-changer in maintaining competitive edges across various industries facing tight turnaround times and stringent accuracy requirements.

Investing in AS/RS technology allows businesses to cut costs on warehouse space and staffing considerably. It ensures that inventory is handled efficiently, reducing error rates associated with manual sorting procedures.

Warehouses equipped with such systems become powerhouses of productivity, operating around-the-clock without compromising service quality or consistency – critical factors for directors seeking to improve their supply chain operations in today’s fast-paced market environment.

Sourcing Software with Market Intelligence

Moving from advancements in sorting and retrieval, sourcing software infused with market intelligence stands as a game-changer for procurement teams. It breathes new life into traditional supply chain practices by offering real-time data on supplier performance, pricing trends, and lead times—empowering decision-makers to act swiftly and strategically.

The power of this software lies in its ability to analyse vast amounts of market information rapidly which enables companies to anticipate changes rather than just react.

This technology is pivotal for those seeking comprehensive understanding and control over their supply chains. Directors can harness the full potential of artificial intelligence (AI) capabilities within these tools, enabling companies to gain an unparalleled edge.

Smart sourcing solutions go beyond simple cost-cutting; they facilitate informed negotiations, robust risk management strategies, and foster long-term competitive advantage by aligning procurement actions tightly with current market conditions.

IoT Track and Trace Devices

IoT track and trace devices are revolutionising the visibility of goods across the global economy and supply chains. Equipped with advanced sensors, these small but powerful tools send real-time updates on the location and condition of products during transit.

Connectivity modules using cellular or satellite technology ensure a constant flow of data, providing an unprecedented level of transparency that was once thought impossible.

Directors should note: as you strive for greater efficiency in your operations, adopting IoT track and trace solutions could be pivotal. The demand for such technologies is on the rise; they’re not only enhancing visibility but also mitigating risks by allowing proactive management of potential supply chain disruptions.

With accurate tracking at your fingertips, decision-making becomes more informed, agile, and responsive to the ever-changing market demands.

Supply Chain Digital Twins

Digital twins are at the forefront of revolutionising tech supply chain management. They create virtual replicas of physical supply networks, allowing for real-time analysis and scenario planning.

These advanced models represent all relationships within the actual supply chain, providing an unmatched level of visibility and transparency. With this technology, companies like DHL and Maersk simulate various scenarios to optimise operations and enhance supply chain resilience dramatically.

Embracing digital twins contributes to a data-driven approach in emerging technology for supply chain management. Currently used by 13% of organisations, they allow decision-makers to test the effect of potential changes without disrupting their operational flow.

This insightful tool is gaining traction as it promises improved situational awareness and actionable guidance towards more efficient, predictive operations amidst a landscape where industry 4.0 continues to redefine possibilities in warehousing industries and beyond.

Intralogistics Robots

Moving beyond digital twins, intralogistics robots are revolutionising warehouse operations. These sophisticated machines are now a common sight at warehouse stations and in distribution centres, where they work alongside humans to streamline the movement of goods.

With the shipment of these robots rising by 45% in 2021 alone, it’s clear that businesses are recognising their value for improving efficiency and precision.

DHL’s $15 million investment into BOSTON DYNAMICS’ Stretch Robots exemplifies this trend towards automation in supply chain management technology. These advanced robots utilise artificial intelligence (AI) and machine learning (ML) to optimise routes within warehouses, drastically reducing errors and increasing accuracy in order fulfilment processes.

This leap forward not only boosts productivity but also enhances supply chain transparency – a critical advantage for companies striving to meet ever-increasing consumer expectations.

AI-Enabled Inventory Optimisation Software

Seamlessly integrating with the advancements made by intralogistics robots, AI-Enabled Inventory Optimisation Software takes supply chain efficiency to new heights. This cutting-edge tool leverages artificial intelligence to process vast amounts of inventory data quickly and accurately.

It empowers companies to maintain minimal stock levels while still meeting customer demands, which is crucial in today’s fast-paced market.

Implementing such technology in supply chain management translates into a streamlined approach for forecasting demand and ensuring that safety stock levels are kept optimal without excess. Retail giants like Amazon and Walmart, along with logistics leaders UPS, have already harnessed the power of this software to automate decision-making processes within their supply chains.

This not only saves time but also reduces human error, making operations more resilient against unpredictable challenges that tech supply chains face today.

IoT-Based Proactive Field Service

IoT-based proactive field service is revolutionising how businesses manage their assets, sharpening the edge in a fiercely competitive market. Equipped with sensors and predictive analytics, this technology transforms maintenance from a reactive chore into a strategic advantage.

By monitoring equipment health in real time, it anticipates issues before they arise, dispatching technicians to the front lines of potential breakdowns with precision. This foresight not only slashes downtime but also curtails excessive spending on spare parts.

Imagine your assets perpetually operating at peak efficiency, as IoT ensures seamless functioning and maximum uptime. Leveraging such smart systems injects agility into operations, empowering your supply chain to respond dynamically to burgeoning demands or unforeseen disruptions.

Next up is exploring how supply chain visibility software further augments these technological strides by offering unparalleled transparency across every touchpoint of the supply chain network.

Supply Chain Visibility Software

Supply chain analytics and visibility software is transforming how directors manage logistics and operations. With real-time tracking enabled by 5G connectivity, these powerful tools offer unprecedented insight throughout the entire supply chain journey.

Companies leverage this technology to access vital metrics that guide decision-making processes. Alerts signal shipping delays instantly, allowing for swift adjustments and maintaining smooth workflow.

Emerging vendors of such software compile vast data pools from different industry players, including port operators and logisticians. This comprehensive information benefits customers by enhancing foresight in transportation timelines.

The integration of this technology stands as a testament to its pivotal role in shaping the future landscapes of supply chain management practices. Directors now have at their disposal a robust system that ensures increased transparency, fostering reliability and efficiency across global networks.

Conclusion

The horizon of supply chain technology brims with promise, offering a landscape where efficiency and innovation converge. Groundbreaking tech revolutions like AI and IoT stand poised to redefine logistics, making this an exhilarating time for industry leaders.

Firms that adapt quickly to these changes will thrive, shaping the future with resilience and agility. Directors must steer their strategies towards harnessing these technologies, securing a competitive edge in the dynamic world of supply chains.

Prepare to embrace this transformative journey; the potential for growth is immense.

FAQs

1. What new technologies are changing supply chain management?

Emerging technologies like blockchain, AI technologies, and cloud-based systems are revolutionising supply chain management by improving efficiency and accuracy.

2. How does technology help in solving supply chain issues?

Tech innovations such as collaborative robots, driverless vehicles, and warehouse management systems (WMS) tackle tech supply chain issues by automating tasks and streamlining order processing.

3. Can blockchain technology influence the future of the supply chain?

Yes, blockchains can transform technology and improve supply chain resilience and chains in managing records securely with improved transparency which aids consensus on transactions without needing intermediaries.

4. Are there any advancements in vehicle technology for logistics?

Advancements include autonomous trucks that promise to disrupt traditional shipping by providing efficient self-driving vehicles capable of delivering goods safely and swiftly.

5. Will the internet improve how businesses manage their inventory?

Definitely! With internet access becoming more robust through networks like Starlink, businesses can now ensure data availability in real-time thus enhancing inventory management using systems such as product lifecycle management (PLM).

6. How is programming contributing to the evolution of SCM technology?

Programming allows for custom-designed solutions that integrate various platforms making them interoperable; this includes automates weigh-in-motion systems used within the digital supply chain.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...