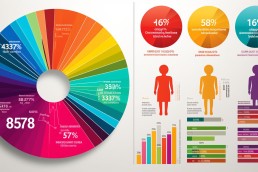

As manufacturing directors, controlling costs while increasing profits is a common challenge. Interestingly, over 60% of activities in a manufacturing business may not add customer value. Our article outlines achievable strategies to reduce manufacturing costs, reduce expenses and strengthen your bottom line. Discover how!

Key Takeaways

Lean manufacturing principles, such as process automation and cross-training employees, can drastically cut labour costs, boost productivity, and reduce waste. These methods streamline operations and ensure that teams are versatile and able to respond quickly to changes in production demand.

Adopting energy-efficient technologies and considering the trade-offs between renting versus owning equipment or property can significantly lower overhead expenses. Remote work options for non-production staff also offer potential savings on facility-related costs.

Reducing material expenditure is pivotal; this can be achieved by using sustainable materials which may attract tax incentives, streamlining your supply chain for better supplier deals, and relentlessly pursuing waste reduction throughout all stages of production.

Optimising product lines through strategies like build-to-order systems and mass customisation allows manufacturers to adapt swiftly to customer demands while minimising inventory holding costs. Standardisation of parts further enhances efficiency by simplifying logistics.

Embracing modern tools such as ERP software aids in managing complex production processes more effectively leading to cost reductions through improved planning accuracy, reduced stock levels, compliance with quality standards, and data-driven decision making.

Understanding Manufacturing Costs

Manufacturing costs split into several categories, with direct expenses like raw materials and labour being most apparent. These direct labor costs and direct material costs are the tangible inputs that go straight into producing goods.

Consider raw material procurement: this is where negotiations with suppliers can play a pivotal role in cost management. Sharp negotiation strategies often lead to better pricing, directly affecting the cost of goods sold.

Indirect expenses also weigh heavily on a manufacturer’s balance sheet. Overhead and indirect costs such as salaries, equipment depreciation, and facility maintenance are significant expense and must be systematically evaluated for possible savings without sacrificing quality or operational efficiency.

Smart inventory management can help reduce holding costs while predictive maintenance schedules keep machinery running smoothly, minimising costly downtimes and extending asset lifespans—all contributing to leaner, lower production costs and healthier gross margins.

Strategies to Reduce Manufacturing Costs – Labour

Streamlining and reducing labor costs is pivotal for manufacturing firms aiming to augment margins without compromising workforce efficacy. Implementing innovative tactics to reduce labor costs can lead to significant savings, thereby enhancing the bottom line and securing a more competitive marketplace position.

Process Automation

Process automation stands as a vital tactic for slashing labour expenses within the manufacturing realm. By embracing technologies like collaborative robots, companies can ensure tasks that are repetitive and time-consuming are handled efficiently, freeing up human workers for more complex duties.

Automated guided vehicles streamline material handling and logistics, reducing the need for manual transportation and minimising error rates.

Predictive maintenance algorithms signal equipment issues before they escalate into costly downtime, safeguarding your production schedule’s integrity. These techniques require upfront investment but pay dividends by enhancing productivity and shaving costs in the long run; it’s essential to conduct thorough cost-benefit analyses to secure a robust return on investment (ROI).

Deploying such smart manufacturing solutions aligns seamlessly with industry 4.0 trends, driving forward into increased operational efficiency reduced labor costs.

Following a strategic approach to automating processes transitions elegantly into exploring how cross-training employees can further optimise your workforce utilisation – another pivotal point of discussion on our journey to cost reduction.

Cross-Training Employees

Cross-training employees boosts your workforce’s flexibility and allows for a more dynamic allocation of resources. By equipping staff with the skills to operate multiple machines and understand different processes, you effectively expand your operational capability without hiring additional specialised workers.

This strategy not only enhances job satisfaction by breaking up the monotony but also creates a team capable of responding swiftly to changes in production demand.

Implementing cross-training can lead directly to labour cost reductions, as it minimises downtime costs incurred during absences or fluctuations in workload. A well-rounded team adapts easily, maintaining productivity levels and ensuring that manufacturing processes stay on track without reliance on external temps or overtime expenses.

It forms part of lean manufacturing principles, focusing on waste reduction through smarter use of human resources—a key factor for directors looking to tighten budgets without sacrificing output quality.

Lean Manufacturing Principles

Building on the foundation of empowering your workforce through cross-training, adopting lean manufacturing principles can take manufacturing cost reduction to the next level. These principles streamline operations, reduce production costs and sharpen your competitive edge by relentlessly pursuing waste elimination across every stage of production.

Lean thinking drives a company towards examining all aspects of their processes, pinpointing areas where resources are being expended without adding value to the end product.

Implementing lean strategies often reveals hidden inefficiencies such as excess stock and unnecessary transportation — these are costly distractions operating costs that sap profitability if not addressed promptly.

By focusing on only what is necessary for creating customer value, lean production minimises over-production and ensures that effort is spent enhancing quality rather than fixing defects later down the line.

This holistic approach aligns closely with modern demands for agility in manufacturing, as it enables quick adjustments to changes in demand while keeping costs low and quality high.

Strategies to Reduce Manufacturing Costs – Overheads

Trimming overhead to reduce costs in both production and manufacturing and reduce labor costs further, is essential in sculpting leaner operations, and by embracing strategies like upgrading to energy-efficient systems, businesses can significantly reduce their expenses and sharpen their competitive edge—unlocking details on these approaches awaits your discovery.

Energy Efficiency

Slashing energy bills is a pivotal move for manufacturing directors aiming how to reduce costs of production and enhance profitability. Investing in cutting-edge, energy-efficient technology not only shrinks your factory’s carbon footprint but also translates into substantial savings on operational costs.

Simple upgrades like switching to LED lighting, optimising HVAC systems, and implementing smart meters can dramatically reduce excess consumption and eliminate waste too.

Executing strategic changes across energy-intensive processes secures a competitive edge. Consider conducting energy audits to pinpoint inefficiencies or adopting ISO 50001 standards that could refine the way you manage power and energy usage.

Manufacturers harnessing these practices often see a significant drop in their own energy costs and expenditures, fostering an environment of sustainability while bolstering the bottom line.

Renting vs. Owning

Deciding between renting and owning manufacturing equipment or property is a pivotal choice for directors aiming to further reduce overhead costs and expenses. Renting may offer flexibility and lower initial costs, but it lacks the long-term equity and potential tax advantages of ownership.

Leaders need to assess their cash flow, tax implications, and strategic goals before opting for one over the other. The cost-benefit analysis should include considerations like maintenance costs, responsibilities, insurance premiums, and the availability of grants or incentives that might sway the decision.

Manufacturing companies face significant outlays on equipment acquisition; weighing up leasing against buying becomes integral to financial planning. Owning equipment outright can lead to substantial capital expenditure but allows firms full control over their assets – an advantage when scaling operations or customising processes extensively.

In contrast, renting can mitigate large upfront investments and align with just-in-time inventory practices by offering access to up-to-date technology without long-term commitment.

Both options come with specific advantages; effective leadership hinges on choosing a path that aligns tightly with the company’s operational efficiency and growth trajectory.

Remote Work Opportunities

Remote work opportunities offer a strategic avenue for manufacturers to trim down their overheads. By allowing non-production staff to operate from home, companies can substantially to save money on office space and utility costs.

This shift not only cuts expenses but also promotes employee satisfaction, which in turn may boost productivity. Moreover, embracing flexible working conditions enables access to a broader pool of talent that might otherwise be unreachable due to geographical constraints.

Leveraging technology paves the way for remote collaboration without compromising operational efficiency within the manufacturing sector. It ensures cost-cutting measures extend beyond just physical space reduction; it minimises investment in expensive office equipment and curtails facility-related expenses like heating or air conditioning.

Looking ahead, reducing material costs becomes another key focal point for enhancing profitability in the competitive arena of manufacturing.

Strategies to Reduce Manufacturing Costs – Materials

In the quest for leaner operations, a strategic approach to reducing material costs can be a game-changer for manufacturing businesses. By scrutinising procurement processes and administrative costs and embracing innovations in materials management, companies unlock significant savings that directly bolster their bottom lines.

Adoption of Sustainable Materials

Switching to sustainable materials not only slashes costs but also resonates with eco-conscious consumers, enhancing corporate reputation. Recycled materials and biodegradable plastics are innovating production lines, cutting down on raw material expenses significantly lower manufacturing costs.

Embracing these alternatives can lead to substantial long-term savings and environmental gains, positioning your company as a responsible industry leader.

Manufacturers adopting green initiatives may find themselves eligible for government tax incentives and grants. This financial support serves as an additional benefit that favours your bottom line while advancing climate change mitigation efforts.

Transitioning towards sustainability is more than a trend; it is a strategic move that promises cost reductions and a competitive edge in today’s conscientious market.

Streamlining the Supply Chain

Streamlining the supply chain can lead to significant time and cost savings in procuring raw materials, directly impacting the bottom line. Efficient management of this complex system is vital for producing high-quality goods while keeping production costs low.

Fostering strong relationships with suppliers ensures consistent, reliable access to necessary components, which reduces delays and enhances your ability to meet market demands promptly.

Optimising these supplier partnerships involves collaborating closely, sharing information, and working together towards mutual efficiency gains. Being proactive about seeking improvement programmes can also introduce innovative practices that further streamline operations.

Supply chain integration not only aligns resources but also harnesses collective expertise to drive process innovation and reduce wastage—crucial steps for maintaining a competitive edge in today’s fast-paced manufacturing landscape.

Waste Reduction

Curbing excess in manufacturing operations is central to driving down costs and enhancing profitability. Waste does not contribute any value from the customer’s vantage point, so pinpointing and removing it becomes a strategic priority.

By integrating lean manufacturing principles, firms can systematically dismantle inefficiencies that bloat expenses without adding worth. This approach not only trims material costs but also aligns with corporate social responsibility goals by mitigating pollution and reducing scrap.

Implementing sustainable materials paves the way for reduced environmental impact and often lowers expenditure over a product’s life cycle. Directors should consider scrutinising every stage of their production process to identify opportunities where waste can be cut out or minimised—such as optimising inventory with just-in-time systems and redesigning products to require less material without compromising on quality.

These measures promise not just immediate savings but also long-term benefits as they contribute to fostering a more resilient supply chain management model that withstands market fluctuations and resource scarcity challenges.

Enhancing Productivity

Enhancing productivity is not merely about working harder but smarter, leveraging innovative strategies that harmonise with your workforce and technology to maximise output while minimising inputs.

This approach fosters a more agile manufacturing process that can quickly adapt to changing market demands and achieve greater economies of scale.

Build-to-Order and Mass-Customised Products

Embracing build-to-order and mass-customised product strategies can significantly reduce manufacturing costs and streamline your manufacturing operations. These approaches align production closely with customer demand, eliminating the need for large inventories and reducing waste.

They allow for a more agile response to market changes, as products are made to specifications upon receipt of orders rather than in anticipation of them. This not only reduces overhead costs but also enhances product personalisation, giving your business a competitive edge.

Deploying standard parts within these custom solutions further refines the manufacturing process by cutting down on setup times and minimising storage requirements. You benefit from economies of scale while still offering variety, creating value both for your firm and your customers.

Clear communication with suppliers ensures that materials arrive just in time for assembly, which cuts back drastically on handling expenses and shipping costs; this tighter supply chain management is key to keeping the costs in manufacturing very low without sacrificing quality or flexibility in product offerings.

Standardising Parts

Moving from the flexible approach of build-to-order and mass-customised products, standardising parts serves as a pivotal strategy on how to reduce manufacturing cost enhance manufacturing efficiency. By adopting uniform components across various product lines, you can significantly reduce setup times and minimise required floor space for inventory.

This leads to streamlined logistics and more effective supply chain management, cutting down overheads direct costs and fixed and variable costs, substantially.

Implementing part standardisation in your production processes paves the way for notable improvements in productivity. It reduces the complexities involved in handling multiple unique parts, allowing machinery and workers to operate with greater speed and less downtime.

Moreover, this approach harmonises your entire manufacturing system, leading to economies of scale that can give you a competitive edge while maintaining quality standards.

Rationalisation of the Product Line

Building on the standardisation of parts, rationalising your product line further streamlines operations by focusing on high-performing products and eliminating underperformers. This strategic move simplifies production processes, optimises inventory levels, and can lead to significant cost savings in supply chain management – up to a remarkable 50%.

Moreover, by trimming down the product portfolio to core offerings, businesses report improved inventory turnover rates; some have even doubled their inventory performance.

Embracing this approach requires directors to critically evaluate each product’s contribution to sales and profit margins. Discarding items that do not add value or align with company strengths allows more resources and energy to be concentrated on those products that truly drive growth.

Such concentration not only enhances quality control but also sharpens your competitive edge in the market. Ultimately, this careful curation of the product line becomes an essential tactic for achieving leaner manufacturing and reducing costs while bolstering productivity across all business fronts.

Simplifying Supply Chain Management

Streamlining supply chain management is a crucial step in reducing manufacturing costs and enhancing profitability. Cloud manufacturing platforms offer an innovative solution, transforming the complexity of production planning, scheduling, inventory management, and material purchasing into a more manageable form.

These platforms enable directors to oversee operations with greater ease while making sure that resources are optimally allocated throughout the supply chain.

Establishing strong connections with suppliers lays the foundation for a cost-effective supply strategy. Collaborative relationships foster trust, pave the way for negotiation of better terms, and ensure timely procurement of materials without sacrificing quality.

Directors can leverage these partnerships to gain insights into market trends and align their production strategies accordingly, reducing unnecessary expenditures caused by last-minute purchases or wasteful stockpiling of resources.

Automation and its Role in Cost Reduction

Automation stands as a pivotal force in the modernisation of manufacturing, directly translating to substantial cost savings. Through advanced automated systems and AI-powered technology, repetitive and time-consuming tasks become streamlined, allowing for enhanced productivity and reduced human error.

Factories equipped with these sophisticated tools can operate around the clock without concerns over fatigue or labour laws associated with human workers.

Investment in automation technology not only minimises labour expenses but also catalyses significant energy savings, by optimising production processes for maximum efficiency and reducing energy consumption. Automated machinery is precision-engineered to use only what is necessary, whether it’s raw materials or electrical power, cutting down on excess energy consumption and waste disposal costs.

This shift towards lean process operations ensures that manufacturers remain competitive by producing higher quality products at lower costs with improved reliability.

The Impact of Manufacturing ERP on Costs and Profits

Manufacturing ERP software emerges as a game-changer in the competitive industrial landscape. It enables companies to cut through complexity by orchestrating seamless and efficient production planning, precise scheduling, and efficient inventory management.

With the right ERP tools in place, businesses can achieve significant cost reductions by aligning material purchasing with how production costs reflect actual market demands. This alignment not only minimises excess stock levels but also prevents costly production delays and overproduction.

The comprehensive capabilities of integrated ERPs are central to identifying and controlling manufacturing expenses. Utilising these systems provides invaluable insights into every aspect of the operational process from floor activities up to strategic planning.

As a result, directors find themselves equipped with robust data analytics that inform smarter budget allocation and cost-saving strategies leading directly to an increased return on investment (ROI).

Moreover, quality management systems embedded within ERPs help pinpoint areas for further continuous improvement initiatives; ensuring compliance standards are met efficiently translates into less waste generation and higher profit margins across the board.

Other Manufacturing Cost-Saving Ideas

Delving deeper into manufacturing efficiencies, we’ll explore innovative strategies that range from revamping your facility layout for streamlined operations to embracing quality control enhancements—each offering significant cost-saving potential without compromising on output.

Optimising Facility Layout and Design

Optimising facility layout and design is a smart move for directors aiming to trim manufacturing costs without compromising quality or productivity. An more energy efficient machinery and equipment layout streamlines workflows, reduces the distance materials travel, and cuts down on unnecessary movement of workers.

This not only saves time but also decreases potential for damage or errors, keeping operations running smoothly.

Maximising space utilisation requires innovative strategies such as incorporating vertical storage solutions and implementing flexible workstations that can adapt to different tasks.

Lean inventory management techniques like just-in-time (JIT) prevent excess stock from piling up and eating into valuable space. These changes result in a more functional environment where fewer resources used are used effectively, leading directly to cost savings and enhanced profit margins.

Enhancing Quality Control and Assurance Processes

Continuing from the smart layout and design of your facility, turning attention to quality control and assurance processes is equally vital for manufacturing and cost reduction strategies. Strong quality management ensures products meet high standards consistently, slashing costs and associated costs associated along with defects or non-compliance.

Implementing rigorous testing protocols at various production stages can prevent defective goods from reaching customers, thereby reducing returns and maintaining brand reputation.

Explore new technologies such as real-time data monitoring and AI-driven predictive analytics to detect potential issues before they become costly problems.

Invest in advanced training programs for staff to understand key performance indicators (KPIs) that directly impact product quality. A well-informed workforce will take proactive measures towards energy conservation, and waste reduction strategies, and efficient resource use—factors instrumental in delivering top-quality products cost-effectively.

Adapting and implementing lean manufacturing principles, techniques and principles like Six Sigma can fine-tune your process excellence efforts by identifying and eliminating inefficiencies that compromise product integrity while improving operational performance across the board.

Outsourcing Non-Core Manufacturing Activities

Enhancing quality control is crucial, but so is recognising when external expertise can benefit your operations. Outsourcing non-core manufacturing activities offers a compelling strategic advantage for many companies.

By handing over these tasks to specialised partners, your business can focus on what it does best – innovating and refining core products.

Companies frequently find that outsourcing leads to cost savings while gaining access to specialised knowledge and high-quality resources. This strategy not only streamlines efficiency but also elevates product quality without the need for extensive capital investment.

Engage with trusted outsourcing partners and watch as they bring in fresh perspectives and skills that complement your business’s strengths, driving you towards greater profitability.

Conclusion – Reduce Manufacturing Costs

Efficiency in manufacturing is key to beating tight profit margins. Employing cost-cutting measures to implement lean manufacturing techniques such as automation and lean principles can lead to significant savings. Smart use of technology, from ERP systems to AI, sharpens competitive edges.

An investment in reducing overheads and material expenses pays dividends down the line. As directors, embrace these strategies for a leaner, more profitable operation.

FAQs

1. What are some effective ways to reduce manufacturing costs?

Instituting energy-saving measures, embracing just-in-time manufacturing principles from the Toyota Production System, and leveraging big data for demand forecasting can majorly cut costs in manufacturing too.

2. How can the Internet of Things (IoT) help lower production expenses?

By using IoT devices, factories gain real-time insights into operations allowing them to conserve and reduce energy, reduce costs in manufacturing itself, manage resources better, and identify bottlenecks swiftly.

3. Can job rotation and on-the-job training really impact manufacturing costs?

Absolutely! These workforce development strategies enhance employee skills which leads to increased efficiency and productivity while reducing errors and eliminating waste too.

4. Why is energy management crucial in cutting down expenses in manufacturing?

Implementing energy conservation practices not only reduces your power bills but also lowers greenhouse gas emissions, contributing to a more sustainable operation.

5. Could artificial intelligence provide a competitive advantage in reducing operational costs?

Artificial intelligence aids in precise extraction of valuable insights from complex data sets which improves decision-making related to inventory management software, control and process optimisation.

6. Do insurance companies offer any benefits that could reduce factory overheads?

Yes, business insurance policies might cover various risks allowing you to invest more confidently in cost-cutting technologies without fearing potential losses.

Like what you see? Then subscribe to our email newsletter. It's not boring!

This is the email newsletter for professionals who want to be on the cutting edge of supply chain management. Every edition is full of fresh perspectives and practical advice.

Your privacy matters! View our privacy policy for more info. You can unsubscribe at anytime.

And there's more...